Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

Carbon fiber, renowned for its strength and lightness in aerospace and sporting goods, is now revolutionizing the construction industry.

Carbon fiber reinforced concrete (CFRC) is a cutting-edge material that combines the best of both worlds: the durability of concrete with the high tensile strength of carbon fiber. In this comprehensive guide, we'll delve into what CFRC is, its advantages over traditional concrete, its diverse applications, and the challenges and future prospects of this innovative material.

Whether you're an engineer, architect, or simply curious about the future of construction, this guide will provide you with valuable insights into how CFRC is transforming the way we build.

What is Carbon Fiber Reinforced Concrete (CFRC)?

Imagine a material that combines the best of both worlds: the strength and lightweight nature of carbon fiber with the durability and versatility of concrete. That's exactly what Carbon Fiber Reinforced Concrete (CFRC) brings to the table. This cutting-edge composite is transforming the construction landscape, offering a high-performance alternative to traditional reinforced concrete.

At its core, CFRC is a type of concrete where conventional steel reinforcements are replaced with carbon fibers.

These incredibly strong fibers act as a backbone, providing the concrete with exceptional tensile strength and flexibility. The concrete matrix , in turn, bonds to the carbon fibers, giving the material its form, compressive strength, and overall durability. This unique combination creates a material that's not only lighter and stronger but also more resistant to the elements.

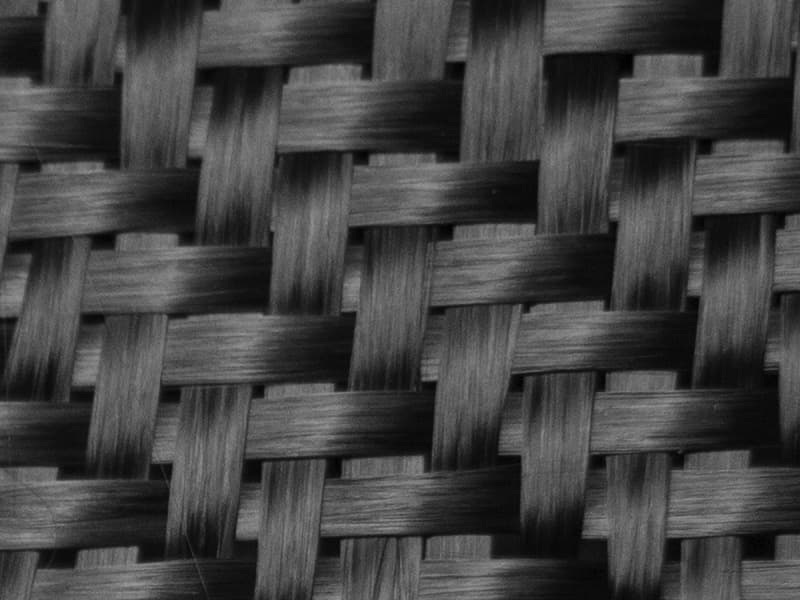

CFRC comes in various forms, depending on how the carbon fibers are incorporated:

- Fabric: Carbon fiber fabric is embedded within the concrete matrix.

- Bars: Similar to steel rebar, carbon fiber bars provide reinforcement with superior tensile strength.

- Laminates: Thin layers of carbon fiber are bonded to the concrete surface for added strength and durability.

Why Use Carbon Fiber Reinforced Concrete?

CFRC has been tried and tested – it offers a range of tangible benefits that are making it increasingly popular in the construction industry:

Strength and Lightness

Pound for pound, CFRC outperforms traditional steel-reinforced concrete in terms of tensile strength. This allows for the creation of structures that are not only stronger but also lighter, reducing the overall load and leading to more efficient designs.

Unrivaled Durability

CFRC is incredibly resistant to corrosion, cracking, and the harsh elements. This exceptional durability translates to a significantly longer lifespan compared to traditional concrete, minimizing the need for costly repairs and maintenance over time.

Design Versatility

Unlike rigid steel reinforcements, the flexibility of carbon fiber opens up a world of design possibilities. CFRC enables the construction of thinner, lighter structures with complex shapes and curves, giving architects and engineers greater creative freedom.

Environmental Responsibility

FRC's lightweight nature and longevity contribute to a more sustainable construction process. The reduced material usage and lower transportation costs associated with CFRC result in a smaller carbon footprint compared to conventional concrete.

Applications of Carbon Fiber Reinforced Concrete

CFRC is a versatile material with a growing list of applications:

- New Construction: Bridges, buildings, and infrastructure projects are increasingly utilizing CFRC to take advantage of its superior strength, durability, and design flexibility.

- Rehabilitation and Strengthening: Aging structures can be revitalized with CFRC. By adding a layer of CFRC to existing concrete, engineers can significantly increase the load-bearing capacity and extend the lifespan of bridges, buildings, and other infrastructure.

- Precast Elements: CFRC is well-suited for prefabricated construction elements. This approach allows for faster and more efficient construction while maintaining high quality and precision.

- Specialized Applications: CFRC's unique properties make it a valuable material for specialized applications like blast-resistant structures and marine environments where corrosion resistance is paramount.

Challenges and Future of CFRC

CFRC is a game-changer, but it's not without its challenges:

Cost

CFRC is currently more expensive than traditional concrete due to the cost of carbon fiber. However, ongoing research and development are working to bring costs down.

Construction Techniques

Working with CFRC requires specialized knowledge and training. As the material becomes more widespread, these skills will become more readily available.

Despite these challenges, the future of CFRC is undeniably bright.

As research continues and production methods evolve, the cost of carbon fiber is expected to decrease, making CFRC a more accessible and cost-competitive option. Andwith growing adoption, specialized training and expertise in working with CFRC will become more widespread, further driving innovation and expanding the potential applications of this remarkable material.

FAQs about Carbon Fiber Reinforced Concrete

We get it – CFRC is a new and exciting material, and you probably have questions. Let's tackle some of the most common ones:

Is CFRC safe?

Absolutely! CFRC is rigorously tested for safety and meets or exceeds building codes and industry standards.

How does CFRC compare to steel-reinforced concrete?

CFRC is lighter, stronger, and more durable than steel-reinforced concrete. It also resists corrosion, making it a great choice for harsh environments.

What are the long-term benefits of using CFRC?

CFRC's longevity means less maintenance and repair over time, saving money in the long run. Plus, its lighter weight can reduce transportation and construction costs.

If you have questions about carbon fiber applications or any details discussed here, connect with us and learn more.

Are you interested in other CARBON FIBER products? Then, visit our store and take a look at our featured collections!

Personal Accessories, Clothing Accessories, Jewelry, Home & Office, Tech, Travel, Gifts, and much more!

Read more CARBON FIBER BLOGS .

The Carbon Fiber Gear Blog is a lifestyle blog for carbon fiber enthusiasts where we talk about carbon fiber gear, fabrication, and news. In addition, we round up the most fantastic carbon fiber products, the best gift ideas, and the uses of carbon fiber.