Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

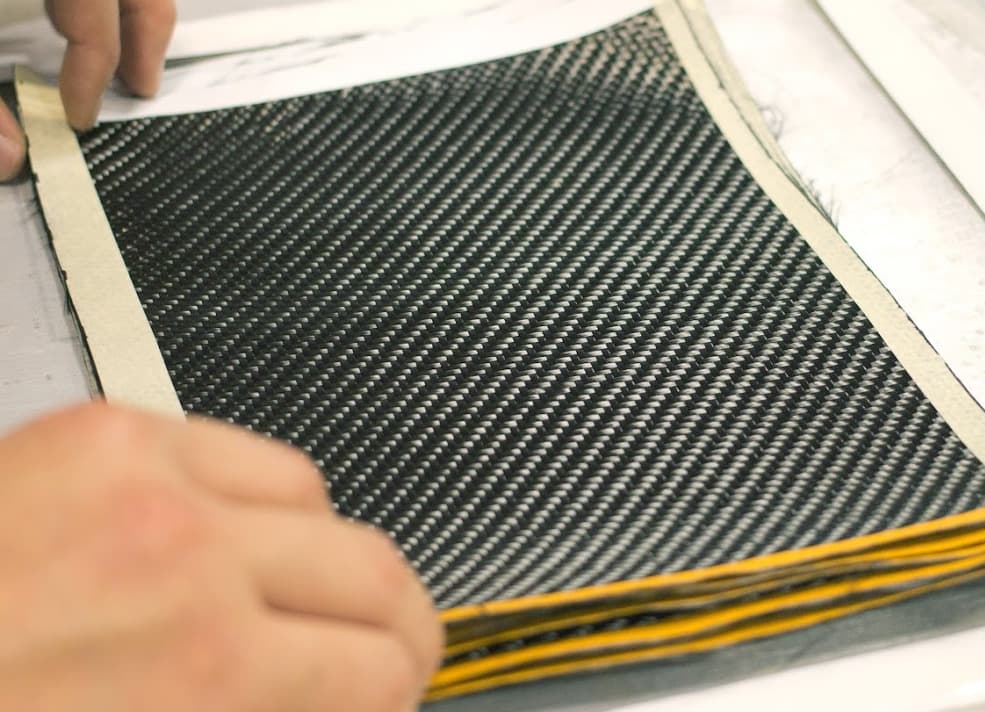

Carbon fiber is stronger than steel, lighter than fiberglass, and more rigid than aluminum. But is it durable? Many factors add to a material's durability. Here's a look at how well carbon fiber withstands wear-and-tear over time.

RELATED: What is Carbon Fiber?

In this article:

- Can Carbon Fiber Rust?

- Can Carbon Fiber Break?

- Does Weather Conditions Affect the Durability of Carbon Fiber?

- Can Carbon Fiber Withstand Heat?

- Is Carbon Fiber Bulletproof?

Can Carbon Fiber Rust?

Carbon fiber is chemically stable, corrosion-resistant, and won't rust. That's why it works well in harsh environments. But strong oxidizing agents, such as hydrogen peroxide or sulfuric acid, may affect it.

Likewise, epoxy resin is inert and won't rust or corrode. It is sensitive to sunlight, though. So, cover carbon fiber composites with a UV resistant finish to prevent long-term damage from sunlight.

It's worth noting that carbon fiber composites may cause galvanic corrosion when in contact with some metals. While it won't lead to evident surface corrosion in the short-term, corrosion products add up and lead to damage with time. Fortunately, this needs specific conditions, and some coatings offer protection.

Can Carbon Fiber Break?

The short answer is yes. Any material can fail, but it's a bit more complicated than that. Many factors, such as the production process, design, and use, affects durability.

For instance, gaps can form, and it's more likely to crack if the manufacturer applies resin unevenly or doesn't use enough. Over time, these small cracks can spread until it breaks. Even minor impacts can eventually lead to failure.

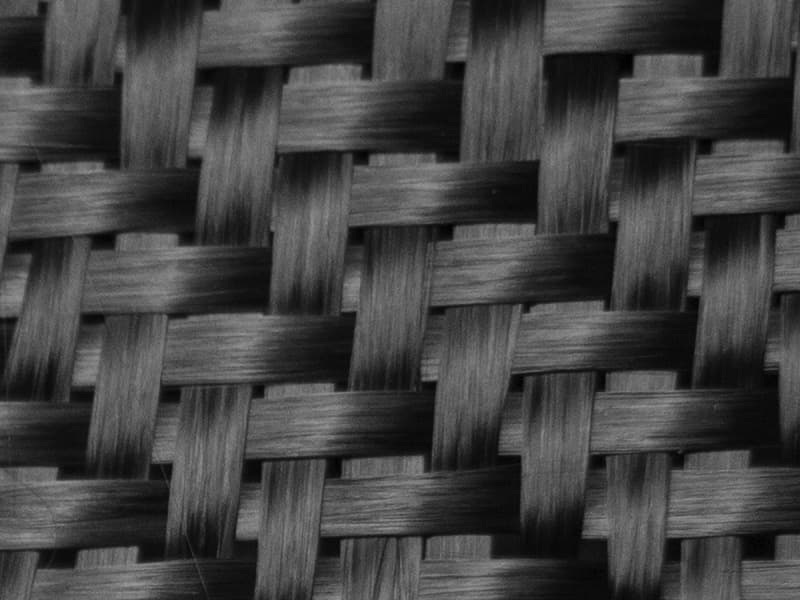

The orientation of the fibers and the fiber layers also has a significant effect on fatigue resistance. As does the type of force you apply. Compression, shear, and tension forces cause different types of failure.

The woven fiber in a 0° layup has less torsional strength than at 45°, for example. So it may break if you twist it.

The bottom line is if you stay under the load threshold for a particular part, it won't break easily.

Also, be aware that it's difficult to detect signs of damage that indicate imminent failure. And unlike other materials that bend or buckle, when carbon fiber fails, it can fail spectacularly and shatter.

RELATED: What is Forged Carbon Fiber? The Ultimate Guide To Forged Composites

Does Weather Conditions Affect the Durability of Carbon Fiber?

Carbon fiber has a low thermal expansion. So, its shape, area, volume, or density doesn't change a lot in response to temperature changes. That doesn't mean it's immune to the effects of weather in the long run. Studies found combinations of weather conditions may have distinct effects on carbon fiber in different settings.

Freeze-Thaw Cycles

The Civil Engineering Research Foundation identified freeze-thaw cycles as a possible threat to carbon fiber durability. Additionally, they found freeze-thaw conditions degrade carbon fiber reinforced concrete more in salty-water.

It's not necessarily the carbon fiber that loses integrity but rather microcracks forming in the matrix and fiber/matrix debonding. And the effects are partly because the structural adhesive isn't as advanced as other carbon fiber uses.

Lastly, despite these effects, another study found carbon fiber reinforced concrete more durable than standard concrete.

Hygrothermal Aging

Hygrothermal aging may have an impact on the durability of carbon fiber in some applications but not in others.

What is hygrothermal aging? Hygrothermal aging refers to a combination of heat and moisture and what effect it has on a structure.

Prolonged exposure to heat and moisture may have little effect on the flexural strength of carbon fiber. But under sustained load and in the presence of saltwater, the tensile strength decreases between 7 % and 12 %.

Wet–Dry Cycles

One study shows wet-dry cycles may have a significant adverse impact on the tensile strength. After 4000 wet-dry cycles, the probability of failure increases notably.

In contrast, it has a limited influence on the deformation of carbon fiber.

UV Exposure and Condensation

UV radiation and condensation operate in a synergistic manner that causes erosion of the epoxy matrix, but it doesn't affect the carbon fiber. The epoxy erosion may ultimately decrease tensile strength by up to 29 % and lead to less durability.

As mentioned, a UV resistant finish will help protect carbon fiber composites.

Overall, weather conditions do affect carbon fiber. But the effects are dependent on how you use it. For instance, weather conditions have a more notable impact on buildings with carbon fiber than a carbon bike frame.

Can Carbon Fiber Withstand Heat?

Carbon fibers can withstand heat. But carbon fiber is mostly used in a matrix such as concrete, plastic, or epoxy, which may limit its heat tolerance. In other words, the matrix plays a more significant role in whether a carbon fiber part can withstand heat than the fiber alone.

For example, some epoxies can withstand temperature up to 100 ℃ ( 212 ℉), whereas carbon fiber reinforced carbon matrix composite can tolerate temperatures above 2000℃ (3632 ℉).

Is Carbon Fiber Bulletproof?

In theory, carbon fiber could stop a bullet, but Kevlar® or other aramid fiber has more flexibility and impact resistance. Besides, Kevlar® is a more cost-effective option for bulletproof armor.

Carbon fiber does offer a high level of protection against some objects. You'll often see race car drivers use it for protection because it disperses the impact of forces. But when it comes to bullets, you'll need many layers to stop it.

Watch this video to see how carbon fiber composite fairs against bullets.

However, carbon nanotubes can withstand bullets. Nanotubes consist of carbon atoms bonded in repeating hexagonal patterns to create a hollow cylinder. These nanotubes can absorb the energy from ballistic missiles better than carbon fiber and, in some cases, even Kevlar®.

At its most basic form, carbon fiber is carbon graphite, which will last virtually forever. The material is typically not photo-degradable or biodegradable. However, some factors do influence its durability, like its matrix. Furthermore, the intense use of composites and environmental factors could affect its durability and potential applications. In general, scientists anticipate carbon fiber parts to last for over 50 years.

We source, design, develop, and curate unique and high-quality products made with carbon fiber and other advanced composite materials. Contact us or visit our website to learn more.

Up Next: