Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

Carbon fiber is becoming more prevalent in a wide range of applications. From supercars to elite-level sports equipment, the biggest name of composite material has proven how superior it is compared to others. However, carbon fiber has yet to impact the rail business, implying that the new material still has more room to grow. Find out how carbon fiber train bogies will make trains lighter for more capacity.

RELATED: Carbon Fiber Wheels for Electric Vehicles to Boost Efficiency of a Car

In This Article:

- What Is a Train Bogie?

- Talgo, Carbon Fiber-reinforced Polymer, and Proprietary Bogies

- Carbon Fiber Train Bogie for Weight Reduction

- Carbon Fiber Train Bogie for Additional Passengers

Carbon Fiber Is Finally Making Its Way to High-speed Passenger Trains

Before we figure out how carbon fiber will have a massive impact on the rail industry, let’s learn what a train bogie is and how this component is crucial to a train.

What Is a Train Bogie?

Technically, a train bogie is a framework that carries a wheelset of a train. As a module of wheels and axles, it may be attached to the rail vehicle or be detachable. In addition, a train bogie may include a built-in suspension or be solid and supported by a separate suspension system.

Simply put, train bogies are the crucial components that allow railway vehicles to move along the track. These modules can be equated with the wheels on cars. However, unlike cars with both wheels connected to one single axle, the wheels on each train side are attached to a separate chassis.

Talgo, Carbon Fiber-reinforced Polymer, and Proprietary Bogies

Who Is Talgo?

Talgo is a Madrid-based Spanish company specializing in designing, manufacturing, and maintaining railroad vehicles. Its mission is to make trains more stable and lightweight by using carbon fiber. Talgo’s strategy is rooted in true manufacturing, meaning that they only rely on their own engineers’ brainpower without using the technology from elsewhere. Talgo’s recent production of carbon fiber train bogies is a part of their plan to understand modern technologies that will become mainstream in years to come.

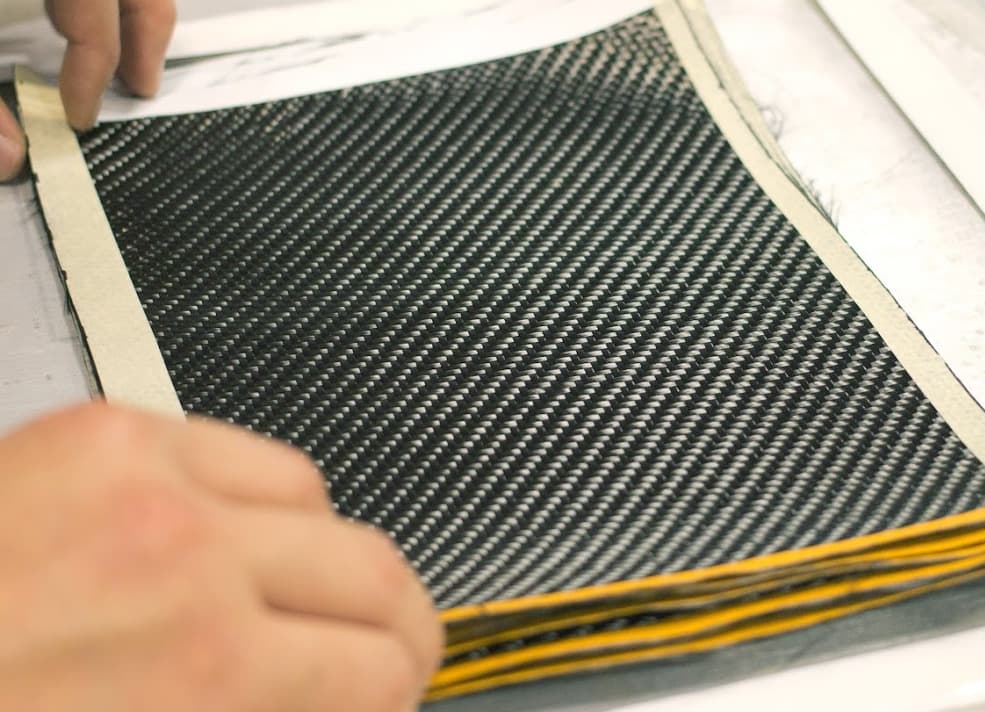

What Is Carbon Fiber-reinforced Polymer?

Carbon fiber-reinforced polymers (CFRP) are carbon fiber-containing plastics that are extraordinarily strong and light. CFRPs are commonly utilized in aerospace, automotive, and sports equipment applications where a high strength-to-weight ratio and stiffness are demanded. CFRP is up to five times lighter than steel and only 60 percent the weight of aluminum. It is fair to say that CFRP is expanding its range of applications and has already proven indispensable in many fields.

What’s New on Talgo’s Proprietary Bogies?

After a careful study of materials, Talgo considered CFRP the best choice for a brand new train concept. Their new proprietary CFRP twin-wheel bogies - Rodals - are different from the traditional bogies, as they contain only one wheel on each side. Conventionally, railway cars use four-wheel bogies (two wheels on each side). In contrast, the Talgo system reduces this number to half, cutting down on the overall weight of the train.

Weight reduction is not the only new feature of the concept. The proprietary Rodal train bogies also feature guided axles, allowing the wheels to operate independently at different speeds around curves. This autonomous operation allows the wheel on the outside of a turn to move faster for more distance covered. On a traditional train with solid bogies, the wheels cannot operate separately, resulting in instability and fatigue on the track.

Carbon Fiber Train Bogie for Weight Reduction

As the bogies are one of the heaviest components of the train, replacing steel with carbon fiber can result in significant weight reductions without affecting the operation or stability. Remember that CFRP is up to five times lighter than steel while equally strong. Therefore, using this material reduces the running gear mass by 50 percent, thus lowering the entire vehicle’s weight.

But, from a passenger’s standpoint, what does it mean to have lighter trains? The answer is that it allows you to have more space on the vehicle.

RELATED: Litespeed Racing Introduces Lightest Carbon Fiber Wheels on the Market

Carbon Fiber Train Bogie for Additional Passengers

The Talgo Avril high-speed train, which can seat up to 600 passengers and operate at 205 mph, will be the first railroad vehicle installed with the new carbon fiber bogies. Talgo has already finalized the full-scale prototype of the bogie for the Avril and successfully passed the fatigue simulation tests. The next step will be running the carbon fiber bogies on tracks under natural conditions for final acceptance.

The new carbon fiber train bogie is also promising to be adopted on other Talgo vehicles to streamline the assembly processes, reduce energy consumption, and minimize track wear and tear.

The day when trains are made lighter to accommodate more passengers is only a few years away. People taking railway trains will then benefit from a better train experience by having more room for seats, moving more easily along the cabins, and reaching the destination faster.

If you have questions about train bogie or any of the details discussed here, connect with us and learn more.

Interested in other CARBON FIBER products? Visit our store and take a look at our featured collections!

Personal Accessories, Clothing Accessories, Jewelry, Home & Office, Tech, Travel, Gifts, and much more!

UP NEXT:

Read more CARBON FIBER BLOGS

The Carbon Fiber Gear Blog is a lifestyle blog for carbon fiber enthusiasts where we talk about carbon fiber gear, fabrication, and news. We will round up the coolest carbon fiber products, the best gift ideas, and uses of carbon fiber.