Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

When performance matters, material choice becomes everything. Carbon fiber and aluminum are two of the most widely used materials in design, manufacturing, and everyday gear, but their differences run deep.

This guide compares carbon fiber vs aluminum across the metrics that matter most: weight, strength, density, cost, and durability. You’ll see where each one excels, where it falls short, and how to decide which is better for your needs.

What Is the Difference Between Carbon Fiber and Aluminum?

Aluminum is a lightweight metal known for being strong, ductile, and easy to machine. It’s been around for decades and is used in everything from airplanes to smartphones to soda cans.

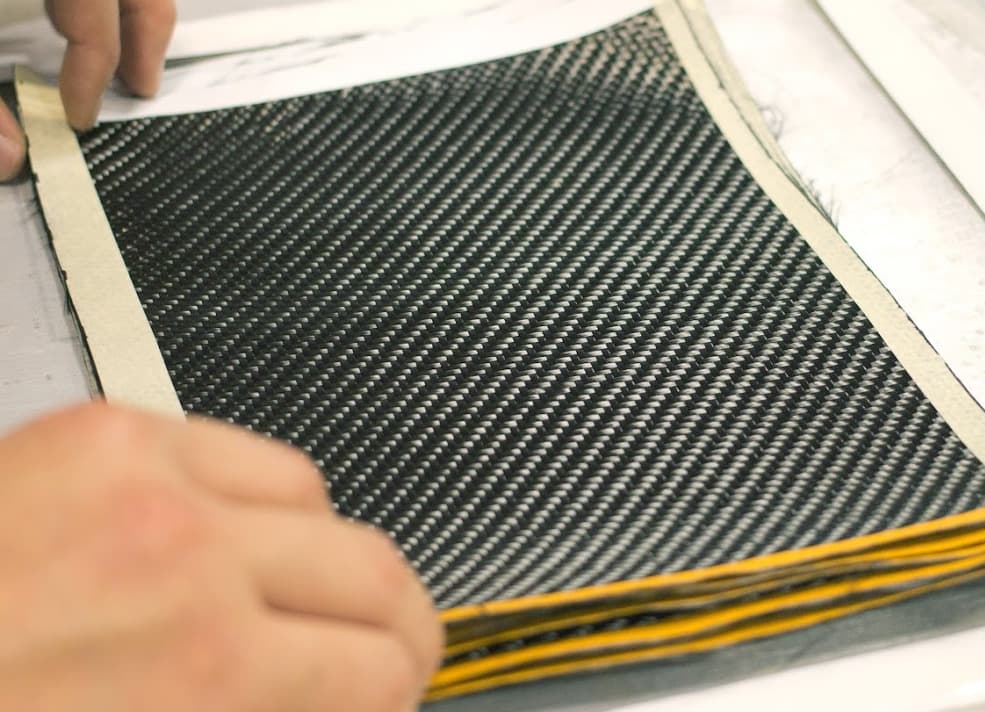

Carbon fiber, on the other hand, is a composite. It’s made by weaving carbon filaments into a fabric and bonding them with a polymer resin. The result is an extremely light, stiff, and strong material that behaves very differently from metal. Unlike aluminum, carbon fiber doesn’t bend or deform. It either holds firm or breaks under extreme force.

Carbon Fiber vs Aluminum: Weight and Density

Carbon fiber is significantly lighter than aluminum.

-

Carbon fiber density: ~1.6 g/cm³

-

Aluminum density: ~2.7 g/cm³

That’s a weight savings of roughly 40 percent. In aerospace and motorsports, this translates to faster speeds and better efficiency. In everyday carry gear, it means less bulk without giving up strength.

Carbon fiber’s real advantage is its strength-to-weight ratio, not just its low mass. This ratio makes it ideal for performance-focused applications where every gram counts.

Is Carbon Fiber Stronger Than Aluminum?

Yes, carbon fiber is stronger than aluminum in tensile strength but weaker in impact resistance and flexibility. Carbon fiber can handle far more force when pulled, while aluminum holds up better under sudden impacts or compression.

The type of strength you need will determine which material is better.

|

Strength Type |

Carbon Fiber |

Aluminum |

|

Tensile (pulling) |

Up to 500,000 psi, extremely strong |

Around 45,000 psi, significantly lower |

|

Compressive (crushing) |

Strong but brittle under overload |

Deforms predictably, more forgiving |

|

Impact resistance |

Brittle, prone to cracking on sharp impact |

Absorbs shock, bends rather than breaks |

Carbon fiber wins on pull strength and stiffness. Aluminum absorbs force, flexes under pressure, and protects against physical damage.

Carbon Fiber vs Aluminum: Pros and Cons

Carbon fiber is lighter, stiffer, and stronger in tension. Aluminum is tougher, cheaper, and easier to work with. Each material brings trade-offs in performance, durability, and cost. Choosing between them depends on what you prioritize — precision and weight savings or impact resistance and fabrication flexibility.

Pros and Cons of Carbon Fiber

PROS

-

Extremely lightweight: Carbon fiber cuts weight by about 40 percent compared to aluminum. The lighter build improves handling, speed, and efficiency across performance-driven products.

-

High tensile strength: The material withstands serious pulling force without stretching or breaking. It's commonly used in aerospace and racing for this reason.

-

Stiff and corrosion-resistant: Carbon fiber stays rigid under pressure and resists rust, salt, and oxidation. Its durability holds up in harsh environments.

-

Customizable layering for directional strength: Manufacturers can adjust fiber orientation to reinforce specific stress points. That kind of precision offers a level of performance aluminum can’t match.

CONS

-

Expensive to produce: Producing carbon fiber involves heat curing, precision layering, and time-consuming fabrication. Those steps drive up the final cost.

-

More brittle under impact: The material doesn’t flex. Instead, it can crack or shatter when dropped or hit, especially if the force exceeds its tolerance.

-

Complex and costly to repair: Carbon fiber often requires full part replacement or expert-level repair. Aluminum, in most cases, bends back or accepts patches.

Aluminum Pros and Cons

PROS

-

Affordable and widely available: Aluminum remains easy to source and cost-effective to work with. Designers across industries rely on it for large-scale production and prototyping.

-

Ductile and impact-resistant: The metal bends under pressure, allowing it to absorb force instead of breaking. That flexibility makes it useful in high-impact or crash-prone environments.

-

Easy to machine and shape: Cutting, welding, and forming aluminum requires basic tools and processes. That flexibility keeps fabrication costs low and timelines short.

-

Naturally corrosion-resistant (with proper treatment): The oxide layer that forms on aluminum protects it from environmental damage. Anodizing or coating increases that resistance further.

CONS

-

Heavier than carbon fiber: The extra weight limits performance in speed- and efficiency-sensitive applications like drones, bikes, or racing builds.

-

Lower strength-to-weight ratio: While strong overall, aluminum can’t deliver the same pull strength or rigidity for its weight.

-

Can deform under stress: Aluminum may bend, stretch, or dent under repeated load or sharp force. That deformation helps in some cases but compromises performance in others.

Carbon Fiber vs Aluminum Price Breakdown

Carbon fiber costs significantly more than aluminum, often 5 to 10 times as much per pound:

-

Aluminum: Around $1.50 to $2.00 per pound

-

Carbon fiber: $10 to $20 or more per pound

Carbon fiber costs more because building it takes more time, labor, and precision. Manufacturers rely on heat curing, resin infusion, and exact layering to produce every piece. That extra effort leads to stronger, lighter, and more specialized components—but also drives up the price.

Aluminum stays more affordable because it’s easy to source, machine, and recycle at scale. It’s the go-to for large production runs, general-purpose use, and projects with tight budgets.

Carbon fiber wins when weight and stiffness matter most. Aluminum makes more sense for cost-sensitive builds, quick prototyping, and parts exposed to frequent impact.

Carbon Fiber Density vs Aluminum

Carbon fiber is much less dense than aluminum, which makes it significantly lighter without giving up stiffness.

-

Carbon fiber: ~1.6 g/cm³

-

Aluminum: ~2.7 g/cm³

Density plays a major role in how a material performs. Lower density means less mass for the same volume, which helps reduce total weight without compromising size or shape. That matters in anything that moves — lighter parts accelerate faster, stop quicker, and wear down slower. Carbon fiber delivers that advantage in every application where speed, control, or efficiency matters.

Which Is Better: Carbon Fiber or Aluminum?

Engineers use carbon fiber when they need to reduce weight without giving up strength, like in aircraft parts, medical equipment, or tech enclosures. They turn to aluminum for parts that need to handle impact, flex under pressure, or stay affordable at scale.

Choose carbon fiber if you want:

-

lightweight structural components

-

rigid builds that won’t flex or fatigue

-

materials that resist corrosion over time

-

high-performance materials used in aerospace, robotics, and advanced manufacturing

Choose aluminum if you want:

-

durable parts for repeated handling

-

components that bend without breaking

-

easy-to-machine pieces at lower cost

-

reliable performance in high-use, budget-conscious applications

Carbon fiber supports innovation where every gram and detail counts. Aluminum remains the go-to for simple, strong, and versatile builds that need to work hard and last long.

Carbon Fiber: Built for Performance. Designed for Everything Else.

Aluminum is practical, tough, and trusted. But when it comes to blending strength, style, and weight savings, carbon fiber is in a league of its own. That’s why you’ll find it in the best bikes, cars, and tools on the planet. And why we’ve built an entire store around it.

Explore our carbon fiber accessories and carry the same performance material used in F1, aerospace, and high-end tech. You’ll feel the difference every time you use it.