Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

Carbon fiber is one of the strongest materials on Earth because of its unique chain-like carbon bonds, yet what makes it truly remarkable is how light it is for its strength. Its tensile strength usually ranges from 3,500 MPa to over 7,000 MPa. Compare that to steel, which comes in at around 400 MPa to 1,200 MPa — even the toughest high-strength alloy steels only reach about 2,000 MPa or 2,600 MPa.

In this blog, we’ll break down what makes carbon fiber so strong, answer whether carbon fiber is the strongest material, show how it stacks up against steel and other materials, and cover what you should know about its real-world performance, weight, and durability. Let’s get into it.

What Is the Tensile Strength of Carbon Fiber?

Tensile strength is the amount of pulling force a material can handle before it breaks. It’s one of the most important measures of strength in design, especially for parts that need to handle stretching or tension without snapping.

Here’s how carbon fiber compares to steel:

|

Material |

Tensile Strength (MPa) |

Tensile Strength (ksi) |

|

Carbon fiber (standard grade) |

~3,500 MPa |

~500 ksi |

|

Carbon fiber (high grade) |

~7,000 MPa |

~1,000 ksi |

|

Steel (standard) |

~400–1,200 MPa |

~60–170 ksi |

|

High-strength alloy steel |

~2,000–2,600 MPa |

~290–380 ksi |

Tensile strength matters because it tells engineers how much load a material can carry without failing.

For example, in car panels, bike frames, or airplane parts, carbon fiber’s ability to handle extreme pulling forces at a fraction of the weight makes it a go-to choice for performance and efficiency.

What Is the Compressive Strength of Carbon Fiber?

Carbon fiber’s compressive strength ranges from 100 to 150 ksi (about 700 to 1,000 MPa), depending on the fiber type and how it’s made. Compressive strength refers to how much force a material can handle when pushed or squeezed. While carbon fiber is excellent under pulling forces (tension), it becomes weaker when compressed.

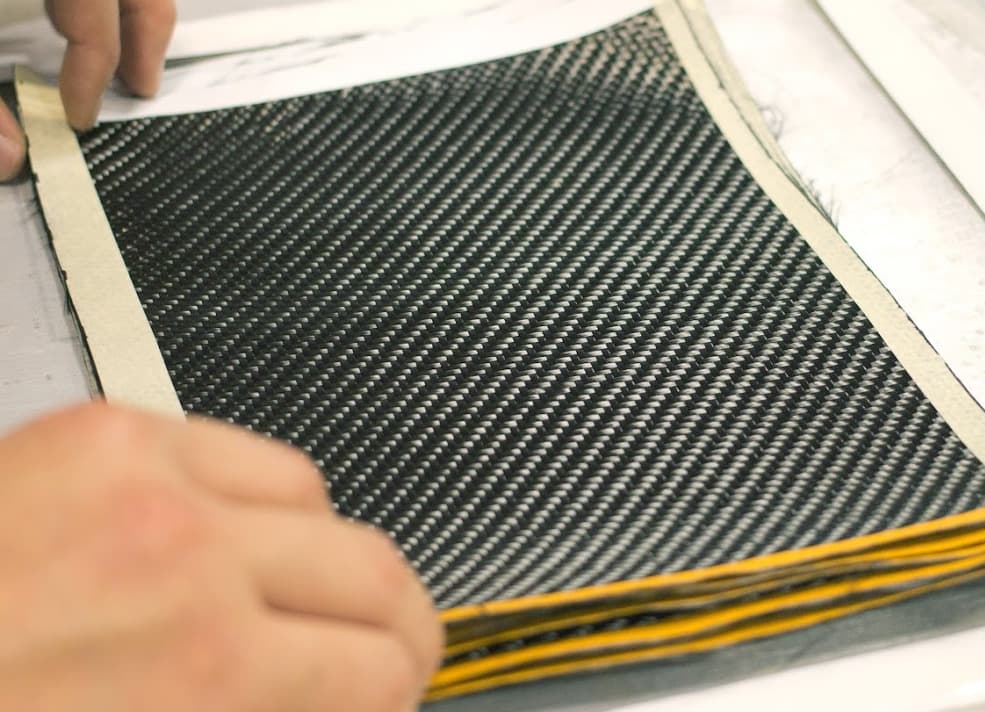

Most carbon fiber parts use resin — a glue-like material that holds the fibers together and creates a strong composite. The fibers are stiff, but the resin can crack when pressed too hard. There are some special cases, like carbon-carbon composites, that skip resin and use carbon itself as the matrix, but these are rare and used mainly in aerospace or extreme heat settings.

Another issue is buckling, which happens when thin or long carbon fiber parts bend and snap under pressure before they even crack.

For context:

-

Steel handles pushing forces very well, with compressive strength similar to its pulling strength.

-

Aluminum has less compressive strength than steel but bends or dents instead of cracking.

-

Some carbon fiber composites improve compressive strength by using stronger resins or special layering designs.

Designers need to plan carefully when using carbon fiber in places where it faces heavy squeezing or crushing forces. They often add reinforcements, change part shapes, or combine materials to reduce the risk of failure.

What Is the Yield Strength of Carbon Fiber?

Yield strength measures how much stress a material can take before it permanently deforms, meaning it won’t bounce back to its original shape. For metals like steel or aluminum, this is a key number.

But for carbon fiber, things work differently.

Carbon fiber doesn’t have a true yield point. Instead, it stays stiff until it suddenly fractures when overloaded. This type of sudden break is called brittle failure, which means the material cracks or snaps without bending or giving any warning.

For an apples-to-apples comparison, here’s how carbon fiber’s strength compares to the yield strength of common metals:

|

Material |

Yield Strength (MPa) |

Tensile Strength (MPa) |

|

Carbon fiber |

N/A (brittle failure) |

~3,500–7,000 |

|

Steel (mild) |

~250 |

~400–550 |

|

High-strength steel |

~1,200–1,400 |

~2,000–2,600 |

|

Aluminum (6061-T6) |

~270 |

~310–350 |

|

Titanium (Grade 5) |

~830 |

~900 |

Because carbon fiber lacks a yield point, designers must account for its sudden failure. With metals, you often get a warning (bending or stretching) before breaking. With carbon fiber, careful design is key to avoid exceeding its ultimate strength.

Is Carbon Fiber Stronger Than Steel?

Yes — when pulled, carbon fiber is much stronger than steel. This pulling strength is called tensile strength, and carbon fiber ranges from 3,500 MPa to 7,000 MPa. Steel, by comparison, ranges from about 400 MPa to 1,200 MPa, with the strongest specialty steels reaching around 2,000 to 2,600 MPa.

|

Property |

Carbon Fiber |

Steel |

|

Tensile strength (pulling force) |

~3,500–7,000 MPa (much higher) |

~400–1,200 MPa (standard), ~2,000–2,600 MPa (high-strength) |

|

Compressive strength (pushing force) |

Lower, resin can crack or buckle |

High, resists compression and handles stress well |

|

Toughness (impact resistance) |

Brittle, prone to snapping |

Tough, bends and absorbs energy without breaking |

|

Weight |

~1.6 g/cm³ (lighter) |

~7.8 g/cm³ (much heavier) |

Carbon fiber has a weakness, though. It doesn’t handle squeezing or pressing forces (called compression) or sudden impacts very well. Steel can bend and take hits without breaking, while carbon fiber is more likely to crack.

Because of its a solid combination of light and strong, carbon fiber is used in:

-

High-performance cars and motorcycles (lighter parts, better speed)

-

Aerospace components (strong but lightweight for fuel savings)

-

Sports equipment (like racing bikes, tennis rackets, and skis)

-

Medical devices and prosthetics (lightweight and strong for better function)

-

Luxury goods (watches, phone cases, wallets for premium feel and durability)

Is Carbon Fiber Stronger Than Titanium?

Carbon fiber is stronger than titanium when it comes to tensile strength (pulling force), but titanium wins in toughness and compressive strength (pushing force). Each material has unique advantages, depending on how and where it’s used.

|

Property |

Carbon Fiber |

Titanium |

|

Tensile strength (pulling force) |

~3,500–7,000 MPa (much higher) |

~900 MPa |

|

Compressive strength (pushing force) |

Lower, resin can crack or buckle |

Much higher, resists compression well |

|

Toughness (impact resistance) |

Brittle, prone to snapping |

Tough, bends and absorbs energy |

|

Weight |

~1.6 g/cm³ (lighter) |

~4.5 g/cm³ (heavier) |

Carbon fiber works best in applications where strength-to-weight performance matters most — like aerospace parts, racing components, or lightweight sports gear. Titanium, on the other hand, is preferred for parts that face high stress, impacts, or heat, such as medical implants, aircraft frames, and high-stress mechanical parts.

How Light Is Carbon Fiber Compared to Steel and Aluminum?

Carbon fiber is extremely light, with a density of about 1.6 g/cm³. Steel comes in at around 7.8 g/cm³, and aluminum at about 2.7 g/cm³.

|

Material |

Density (g/cm³) |

Tensile Strength (MPa) |

Strength-to-Weight Ratio (MPa·cm³/g) |

|

Carbon fiber |

~1.6 |

~3,500–7,000 |

~2,200–4,400¹ |

|

Aluminum |

~2.7 |

~300–550 |

~110–200¹ |

|

Steel |

~7.8 |

~400–1,200 |

~50–150¹ |

The strength-to-weight ratio explains why carbon fiber is so popular. It offers up to 40–50 times the strength-to-weight performance of steel and 10–20 times that of aluminum, depending on the grade (Granta Design, 2021). Industries focused on performance and efficiency — like aerospace, motorsports, and cycling — rely on carbon fiber for critical components.

How Does Carbon Fiber Perform in Real-World Conditions?

Carbon fiber performs best when used for strength and weight savings — not for impact or compression. Its strengths shine in areas where parts face steady pulling forces, low-impact loads, or environments where weight reduction boosts speed, handling, or fuel efficiency. That’s why industries like aerospace, motorsports, and cycling rely on carbon fiber for critical components.

At the same time, carbon fiber has limits. How well it holds up depends on the conditions it faces:

|

Condition |

How Carbon Fiber Performs |

|

Heat |

The carbon fibers handle high temperatures, but the resin (the glue holding fibers together) can weaken around 100–200°C. |

|

Cold |

Stays strong in extreme cold and does not turn brittle like some metals. |

|

UV exposure |

Sunlight can break down the resin over time, causing surface damage; protective coatings help prevent this. |

|

Fatigue |

Resists repeated bending or stress better than many metals but can fail suddenly if pushed too far. |

Even with its advantages, carbon fiber has weak spots engineers must manage:

|

Common Weak Spots |

Description |

|

Cracking |

Can crack from heavy hits or drops. |

|

Delamination |

Resin layers can start peeling or separating under stress. |

|

Overloading |

Thin or poorly designed parts can break suddenly when overloaded. |

Many people don’t realize carbon fiber can stay strong for decades with the right care. Regular checks, protective coatings, and early repairs for small cracks or delamination help keep it performing like new, even after years of use. Many carbon fiber parts are also repairable, which gives them a longer working life than most materials.

How to Maintain Carbon Fiber

Lifespan depends on how well you protect the resin matrix, which shields the carbon fibers and gives carbon fiber its smooth, polished look.

Here’s how to keep carbon fiber strong, sleek, and looking its best over time:

-

Protect from UV by storing items indoors or under covers and applying UV-resistant waxes, sealants, or wraps. Sunlight can weaken the resin over time.

-

Avoid extreme heat or thermal swings. While the carbon fibers handle heat, the resin can soften or develop micro-cracks under stress.

-

Keep items dry after water exposure, since long-term moisture combined with heat can affect the resin matrix.

-

Clean gently with pH-neutral soap, microfiber cloths, and soft towels. Stay away from harsh chemicals, stiff brushes, or abrasive tools that can damage the surface.

-

Prevent scratches, chips, or impacts by using padded covers, handling with care, and keeping carbon fiber away from sharp objects or heavy stacking.

-

Inspect regularly for cracks, delamination (layer separation), dents, or yellowing. Small surface issues may be cosmetic, but deeper cracks or soft spots need professional repair.

-

Store carbon fiber in cool, dry spaces without putting constant stress or pressure on any one area.

With proper care, carbon fiber can last:

-

5–10 years or more for small accessories like keychains, wallets, or bags when it comes to keeping the aesthetic appearance fresh and glossy. The carbon fiber material itself will stay structurally sound far longer, but the outer clear coat or resin surface may show wear over time from daily use.

-

10–20 years for car accessories or trim pieces, depending on UV exposure and stress.

-

Several decades for larger, structural parts like aerospace components or performance gear when properly maintained.

FAQ: Carbon Fiber Strength

-

Can carbon fiber break easily?

No, carbon fiber resists pulling forces very well but can crack or snap under sharp impacts or heavy compression. It is strong but brittle.

-

Is carbon fiber actually strong?

Yes, carbon fiber has a tensile strength of 3,500–7,000 MPa, far stronger (per weight) than steel or aluminum.

-

Can carbon fiber stop a bullet?

No, carbon fiber is not bulletproof. While strong, it is brittle and lacks the flexible, energy-absorbing properties needed for ballistic protection.

-

How much force does it take to break carbon fiber?

It depends on the grade and design, but carbon fiber typically withstands 500–1,000 ksi (tensile) before breaking. Improper loading or impacts reduce this.

-

Is carbon fiber stronger than Kevlar?

In tensile strength, yes — carbon fiber is stronger. But Kevlar offers better toughness, flexibility, and impact resistance.

Carbon Fiber Strength in Everyday Life

Carbon fiber offers incredible tensile strength — 3,500–7,000 MPa — paired with ultra-low weight (~1.6 g/cm³), making it one of the strongest materials available for its size. While it is brittle under impact or compression, careful design unlocks its unmatched strength-to-weight advantage.

You’ll find carbon fiber everywhere: in high-performance cars, aerospace components, racing bikes, sports gear, luxury tech, wallets, bags, and accessories.

At Carbon Fiber Gear, we bring these performance benefits into everyday products. Whether you’re shopping for a sleek carbon fiber wallet, keychain, phone case, or accessory, you’re carrying a piece of cutting-edge material science — strong, lightweight, and made to last.

Check out the full collection today and experience carbon fiber up close.