Hey, you!

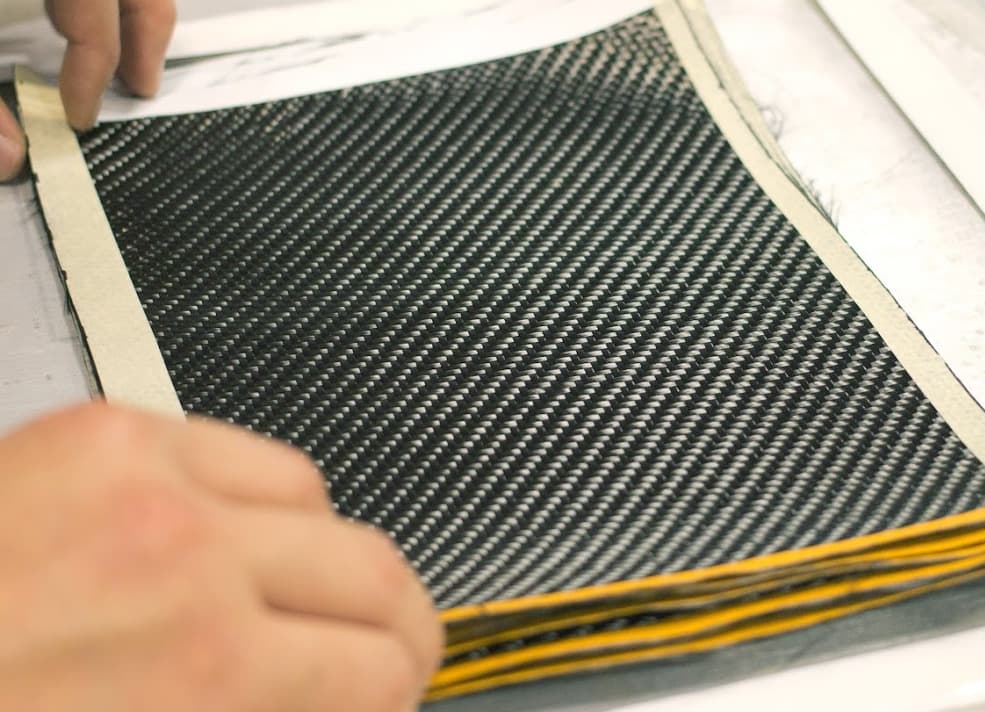

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

Carbon fiber isn’t some brand-new, futuristic material—it’s been proving its worth for decades. Born in high-performance industries like aerospace and motorsports, it quickly became a defining material in Formula 1 racing, where its unmatched strength-to-weight ratio delivered both speed and safety. But for a long time, it was reserved for elite applications, far from the reach of everyday drivers.

That’s finally changing. After years of refinement and cost barriers, carbon fiber is making its way into mainstream automotive design—and nowhere is that more exciting than in electric vehicles (EVs). When you pair cutting-edge EV innovation with the lightweight power of carbon fiber, you get something faster, more efficient, and engineered for the future. It’s a perfect match, and we’re here for it.

What Makes Carbon Fiber the Perfect Match for Electric Vehicles?

Carbon fiber has long powered aerospace and Formula 1—but now it’s set to transform everyday electric vehicles. Here’s why this material is a perfect fit for EVs:

1. Speed & Efficiency with a Lighter Build

Carbon fiber is much stronger than steel yet five times lighter. This means cars built with it weigh less, which boosts acceleration and handling. In fact, studies confirm that its strength far surpasses steel’s, ensuring that every bit of power is used efficiently.

2. Enhanced Energy Efficiency

With less weight on the road, an EV needs less energy to get moving. This directly translates to longer ranges on a single charge—meaning fewer stops and more time enjoying the drive.

3. Design Flexibility for Sleeker Looks

Carbon fiber can be molded into complex shapes, offering new design possibilities that traditional materials can’t match. This flexibility lets engineers create smoother, more aerodynamic car bodies that improve both style and performance.

4. Instant Torque for Exhilarating Acceleration

Electric vehicles already deliver an impressive surge of power thanks to instant torque. The benefits of this quick response are even more thrilling when combined with the lightweight efficiency of carbon fiber.

Remember when we thought flying cars would be a reality by 2050? We might not be soaring yet, but electric vehicles that are lighter, quicker, and more efficient are bringing that futuristic vision closer to home.

Where Is Carbon Fiber Being Used in EVs Today?

Carbon fiber are forcing car engineers and designers to go back to their blue prints, from body structure to performance components. Its high strength-to-weight ratio, ability to absorb energy efficiently, and resistance to corrosion make it a superior alternative to metals in key areas of EV construction.

1. Chassis & Body Panels

The chassis holds everything together and protects passengers, but traditional materials like steel and aluminum add weight. Carbon fiber offers the same strength without the extra bulk, improving both performance and efficiency.

-

Reducing weight leads to quicker acceleration and sharper handling.

-

Unlike metal, carbon fiber won’t rust or corrode, giving it a longer lifespan.

-

BMW used carbon fiber-reinforced plastic (CFRP) for the i3’s passenger cell, making the structure lighter and stronger than conventional designs.

2. Battery Casings & Enclosures

EV batteries are heavy and sensitive to heat, which can impact performance and lifespan. Using carbon fiber in battery enclosures helps reduce weight while improving thermal management, preventing overheating and extending battery life. This material also improves structural protection, making battery packs more resistant to damage in a collision

3. Structural Components & Crash Safety

Unlike steel, which bends and transfers force, carbon fiber absorbs impact energy and disperses it across the structure, making it one of the most effective materials for crash protection.

Engineers use it to reinforce critical safety areas, ensuring vehicles stay strong without unnecessary weight. Crash simulations have shown how carbon fiber improves energy absorption, reducing the force felt by passengers.

4. Interior & Aesthetic Elements

Carbon fiber isn’t just about performance—it’s a popular choice for interior design because of its lightweight and high-end appearance. Automakers are incorporating it into steering wheels, seats, dashboards, and trim pieces.

5. Wheels

Lighter wheels make a big difference in how a car drives, and carbon fiber is increasingly being used to improve performance and efficiency.

Reducing unsprung weight helps with acceleration, braking, and handling, giving EVs a more responsive feel. Many high-performance models are already using carbon fiber wheels to enhance range and efficiency, thanks to their ability to reduce rotational mass.

Why Carbon Fiber Makes EVs Perform Better

EVs are already breaking barriers, delivering insane acceleration and efficiency straight out of the factory. But what happens when you mix instant torque with the lightweight power of carbon fiber? The results could change how we generate power.

While implementation depends on cost, manufacturing, and design choices, the potential is there. And honestly, that’s what gets us excited.

1. Lightweight Construction = Faster Acceleration

Less weight. More speed. Simple math, right? Carbon fiber might help EVs shed unnecessary pounds, making them even quicker off the line.

A lighter car means quicker 0-60 mph times and better efficiency—something automakers are actively exploring.

Reducing inertia makes the car more responsive to throttle inputs, which could mean snappier acceleration and a more engaging drive.

EVs already launch like rockets thanks to their instant torque—cutting weight might just take that gut-punch acceleration to another level.

2. Increased Range & Battery Efficiency

More range. Fewer stops. That’s the EV dream, right? Carbon fiber could make that a reality by cutting down on unnecessary weight, helping batteries work smarter, not harder.

Less strain on the battery could mean a longer lifespan, potentially reducing the need for early replacements.

Battery tech is improving fast, but range anxiety still lingers. Lightweight materials like carbon fiber could help squeeze more miles out of every charge—no bigger battery required.

3. Better Handling & Stability

Speed is one thing, but handling? That’s where things get fun. Lighter cars tend to be more agile, and when you throw in carbon fiber’s rigid chassis properties, you get a formula for sharp, precise cornering.

A stiffer, lighter chassis could enhance cornering ability, which performance EVs need to stay competitive.

Combined with a low-mounted battery pack, a lightweight structure might result in even better stability and balance on the road.

Imagine an EV with race-car-level agility—carbon fiber might just be the key to making that happen.

The Potential Is Huge—But It’s Not That Simple

We know carbon fiber has the right properties to make EVs lighter, faster, and more efficient, but real-world applications depend on manufacturing complexity, cost, and how automakers integrate it into their designs. That said, it’s a tool engineers can use to push EV performance even further.

Which EV Makers Use Carbon Fiber?

Carbon fiber isn’t just for concept cars and one-off builds anymore. Some automakers are already pushing it into production, using its lightweight strength to make electric vehicles faster, more efficient, and better to drive.

Here are a few brands leading the charge:

1. BMW i3

BMW took a bold step by making the i3 the first mass-produced EV with a carbon fiber-reinforced passenger cell. Unlike other early electric cars that stuck to traditional materials, BMW went all-in on lightweighting:

-

The i3’s carbon fiber-reinforced plastic (CFRP) body made it significantly lighter than other EVs in its class.

-

The weight savings helped offset the battery pack’s mass, improving range and efficiency.

While the i3 is no longer in production, its legacy lives on as one of the first EVs to mainstream carbon fiber technology.

2. Tesla’s Carbon-Wrapped Motor

Tesla loves keeping its innovations under wraps—literally. The company has developed a carbon-wrapped rotor motor, allowing its Plaid models to achieve higher RPM limits and increased efficiency.

-

Carbon fiber’s high tensile strength prevents the motor from expanding under extreme forces, keeping it stable at high speeds.

-

By reinforcing the rotor with carbon, Tesla can push performance without adding unnecessary weight.

Elon Musk himself confirmed the technology, though Tesla hasn’t shared all the details yet.

3. Lotus Evija

The Lotus Evija is a hyper-EV designed for brutal acceleration and razor-sharp handling—and it all starts with a full carbon fiber monocoque:

-

The Evija weighs just 3,700 pounds, which is ultralight for a 1,972-horsepower electric car.

-

The monocoque chassis is also stiff and strong, improving aerodynamics and handling.

Lotus used carbon fiber in the body panels, interior, and structural components, proving that lightweight materials can work at extreme power levels.

4. Porsche Mission X

Porsche doesn’t mess around when it comes to performance every element of the MIssion X design—from the lightweight construction to the aerodynamics—is aimed at maximizing speed and efficiency:

-

The Mission X features a full carbon fiber chassis, making it one of the lightest and most aerodynamic hypercars ever designed.

-

With a power-to-weight ratio of roughly one horsepower per kilogram, Porsche is proving that carbon fiber is essential for building the next generation of high-performance EVs.

While it’s still a concept, the Mission X gives us a preview of how Porsche might use carbon fiber in future electric sports cars.

And as production costs come down, we might just see more everyday EVs getting the carbon fiber treatment—bringing the kind of weight savings and performance benefits once reserved for race cars into the real world.

What’s Next for Carbon Fiber in Electric Vehicles?

As costs drop and technology improves, this material could play an even bigger role in shaping the next generation of electric vehicles. We’re zeroing in on what’s on the horizon:

1. Carbon Fiber Structural Batteries – Lighter, Stronger, and More Efficient

Imagine if the car’s body wasn’t just a frame—but part of the battery itself. That’s the idea behind carbon fiber structural batteries, a technology that could take EV lightweighting to the next level.

Carbon fiber stores and conducts energy, meaning it could replace traditional battery enclosures while still serving as part of the car’s structure.

Using carbon fiber for both energy storage and chassis support would cut unnecessary weight, increasing efficiency.

Research is already underway to integrate carbon fiber batteries into future EV designs, reducing reliance on heavy lithium-ion packs.

If this tech makes it to production, EVs could become lighter, stronger, and longer-lasting—all in one move.

2. Lower Production Costs & Mass Adoption

Carbon fiber’s biggest barrier? It’s expensive. But that might not always be the case.

Advancements in manufacturing—including new production techniques and material recycling—could bring costs down, making carbon fiber more accessible.

Automakers are investing in faster, more scalable carbon fiber production, which could make it feasible for mid-range EVs, not just hypercars.

As carbon fiber becomes more affordable, we could see more mainstream electric cars shedding weight and gaining efficiency.

We’ve seen this before—tech that starts in high-end performance models eventually makes its way into everyday cars.

3. Hypercars to Mainstream Models – The Trickledown Effect

Right now, carbon fiber dominates the world of hyper-EVs like the Lotus Evija and Porsche Mission X. But history tells us that cutting-edge technology doesn’t stay exclusive forever.

Performance EVs push the limits of carbon fiber engineering, paving the way for wider adoption.

Lessons learned from hypercar manufacturing could help automakers bring lightweight materials to affordable EVs.

As battery efficiency and range improve, automakers might use carbon fiber to optimize energy use, rather than just for high-speed thrills.

We’re already seeing hints of this with cars like the BMW i3—and as manufacturing gets smarter, carbon fiber could be the next big leap for EV efficiency.

Bring Carbon Fiber Into Your Everyday Life

We may not be building electric hypercars, but our love for carbon fiber runs deep. Whether it’s making EVs lighter, faster, and more efficient or upgrading everyday essentials, this material is all about performance and style.

If you’re as obsessed with carbon fiber as we are, why not bring some of that high-tech magic into your daily routine? From sleek wallets to durable accessories, carbon fiber isn’t just changing the future of EVs—it’s changing the way we carry, travel, and live.

Explore our collection and add a touch of carbon fiber to your everyday gear.