Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

Carbon fiber isn't born — it's forged. Intense heat and meticulous engineering transform humble organic polymers into the feather-light, yet insanely strong fibers we obsess over. But here's the kicker: not all carbon fiber is created equal. The final product's unique personality depends on a few secret ingredients: the type of starting material, the specific recipe used in the manufacturing process, and the way those fibers are woven together.

Think of it like a high-performance athlete: some are built for explosive power, others for endurance. Similarly, different types of carbon fiber excel in specific arenas. Some boast incredible stiffness and strength, perfect for holding up massive structures or resisting intense forces. Others flex their muscles in tensile strength, able to stretch and bend without snapping, making them ideal for applications that demand a bit more give.

Choosing the right carbon fiber for the job is like picking the right tool for the job. Whether it's a high-tech racing bike, a drone that can zip through the air, or a sleek carbon fiber wallet that'll last a lifetime, each application requires a specific type of carbon fiber to unleash its full potential.

Let's delve deeper into the world of carbon fiber and explore the different types that make this material so versatile and indispensable across industries.

Carbon Fiber Types by Strength

In the world of carbon fiber, "tensile modulus" is the name of the game. It's a measure of stiffness, indicating how much a material resists stretching under tension. Think of it as the backbone of carbon fiber's performance – the higher the modulus, the stiffer and less prone to deformation the material becomes. This makes it a critical factor in determining the right type of carbon fiber for different applications.

Standard Modulus (SM)

The workhorse of the carbon fiber world, SM fibers offer a good balance of strength, stiffness, and affordability. They're commonly used in a variety of applications, including sporting goods, automotive parts, and everyday items like phone cases and wallets.

Intermediate Modulus (IM)

IM fibers strike a balance between stiffness and tensile strength. They're a versatile choice for applications that require a blend of both properties, such as bicycle frames and fishing rods.

High Modulus (HM)

HM fibers are known for their exceptional stiffness and strength. They excel in high-performance applications where weight savings and rigidity are paramount, like aerospace components, race car parts, and high-end sporting goods.

Ultra High Modulus (UHM)

UHM fibers are the pinnacle of carbon fiber technology, boasting the highest stiffness and tensile strength. They're typically reserved for the most demanding applications, such as satellite components, aerospace structures, and specialized industrial equipment.

Carbon fiber is categorized into several types based on its tensile modulus, ranging from the more flexible standard modulus to the ultra-rigid ultra-high modulus. Getting to know these classifications is essential for choosing the ideal carbon fiber for your specific needs, whether it's for a lightweight bicycle frame, a high-performance racing car part, or a stylish everyday accessory.

Carbon Fiber Types by Weave Pattern

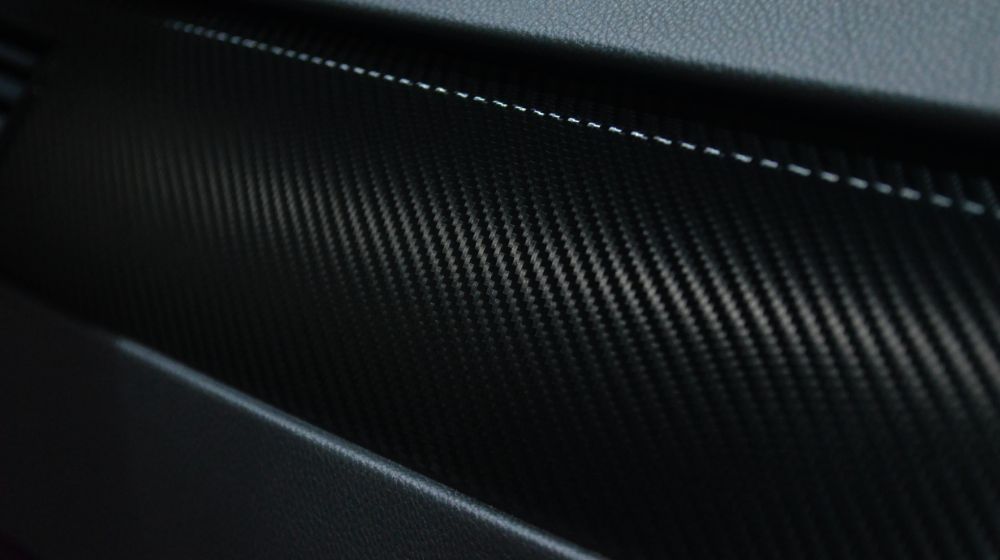

The way carbon fiber threads significantly impacts the material's strength, flexibility, and overall performance. Different weave patterns create distinct characteristics that cater to specific applications.

Let's explore the most common types of carbon fiber weaves and how they influence the material's properties:

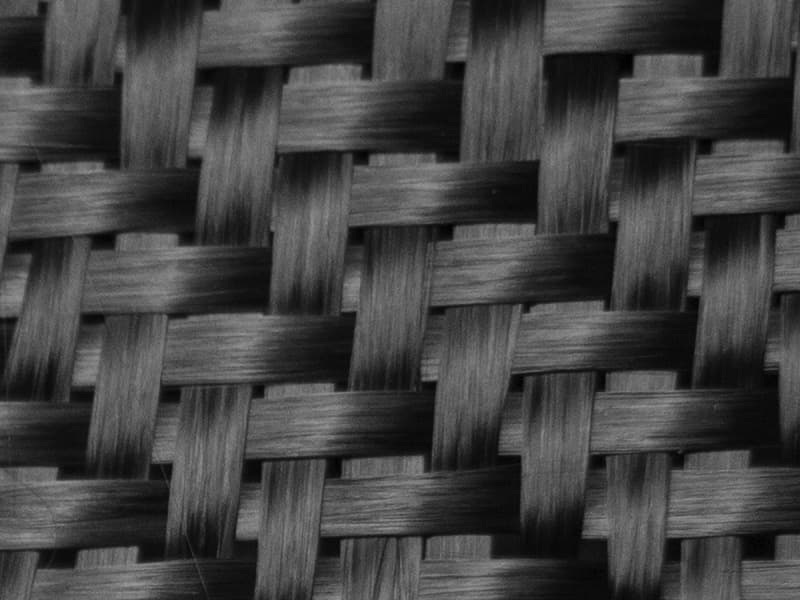

Plain Weave

The classic checkerboard pattern is the most recognizable and widely used weave in carbon fiber. It offers balanced strength in both directions, making it versatile for a wide range of applications. The plain weave is also relatively simple to produce, contributing to its affordability. However, its drapability (ability to conform to complex shapes) is limited compared to other weaves.

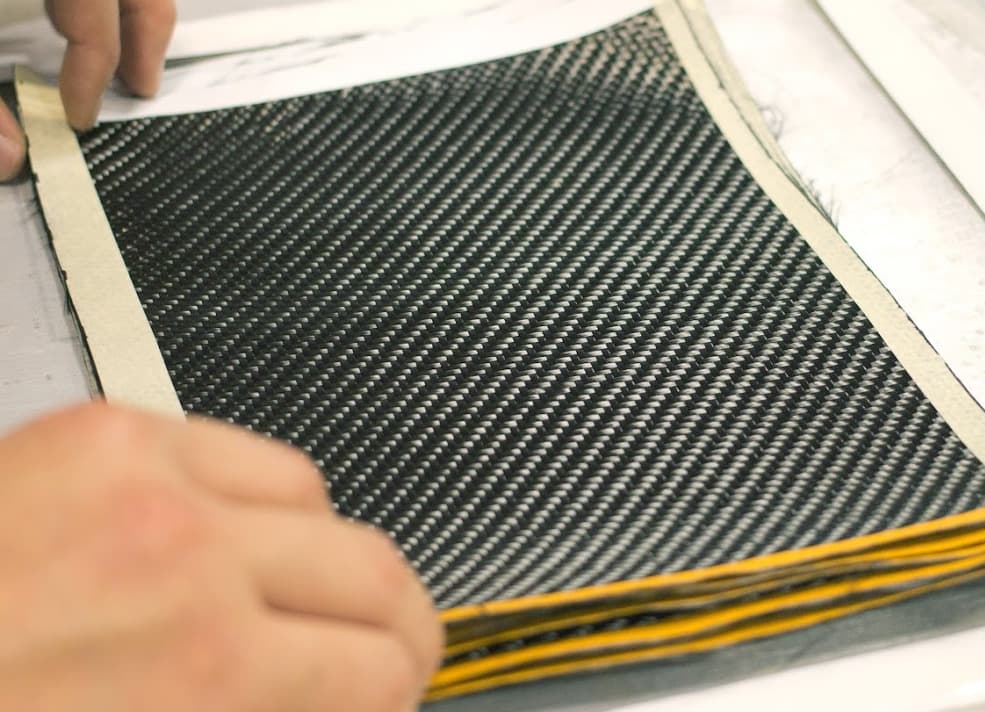

Twill Weave

This diagonal weave pattern is known for its excellent drapability, making it suitable for complex shapes. It also offers good impact resistance.

Satin Weave

With its smooth, glossy finish, satin weave carbon fiber is often chosen for aesthetic reasons. It's commonly used in luxury goods and high-end automotive parts.

Unidirectional

While not technically a weave pattern, unidirectional carbon fiber is worth mentioning. In this arrangement, all fibers run parallel to each other, resulting in maximum strength in one direction. Unidirectional carbon fiber is often used in combination with other weaves to reinforce specific areas of a structure or component.

For most of us, carbon fiber's allure is two-fold: its striking appearance and its impressive performance. The weave patterns we see on carbon fiber parts also lends itself to the material's unique structure and properties.

Different weave patterns, like the classic plain weave, the dynamic twill weave, or the luxurious satin weave, offer varying levels of strength, drapability, and overall performance.

Forged Carbon Fiber: The Exotic Cousin

Forged carbon fiber, also known as chopped carbon fiber, is like the rebellious cousin of traditional woven carbon fiber. It breaks the mold (literally) with its unique manufacturing process and distinctive aesthetic, making it a favorite among those who crave a blend of performance and edgy style.

What Sets Forged Carbon Fiber Apart?

Unlike the meticulously woven patterns of traditional carbon fiber, forged carbon fiber has a more organic, marbled appearance. This is due to its manufacturing process, where chopped carbon fibers are mixed with resin and then compressed into a mold under high pressure and heat. The result is a material that looks like a piece of abstract art, with swirling patterns and a slightly textured surface.

The Forging Process

The beauty of forged carbon fiber lies in its controlled chaos. The chopped fibers are randomly oriented within the resin, creating a unique pattern every time. This unpredictability adds to its allure, making each forged carbon fiber piece truly one-of-a-kind.

Beyond Aesthetics: Forged Carbon Fiber's Strength and Versatility

Forged carbon fiber boasts impressive strength and stiffness, making it a viable alternative to traditional carbon fiber in many applications. It's also relatively easy to mold into complex shapes, making it ideal for intricate designs and components.

Applications of Forged Carbon Fiber

Forged carbon fiber is making waves in the automotive world, appearing in high-performance car parts like spoilers, diffusers, and interior trim. Luxury automakers like Lamborghini and McLaren have embraced forged carbon fiber for its unique aesthetic and lightweight properties.

But the automotive industry isn't the only one benefiting from this innovative material. Forged carbon fiber is also finding its way into luxury watches, jewelry, and other high-end accessories, where its distinctive look and technical prowess make a bold statement.

Choosing the Right Carbon Fiber: A Practical Guide

When shopping for carbon fiber products, it's easy to get overwhelmed by the variety of options available. But don't worry, understanding a few key factors can help you make an informed decision.

Strength and Weight: Finding Your Balance

Different types of carbon fiber offer different levels of strength and stiffness (known as modulus). Generally speaking, higher modulus carbon fiber is stiffer and stronger but also more expensive. So, what's the right balance for you?

-

Everyday Essentials: For items like wallets, phone cases, or sunglasses, standard modulus (SM) carbon fiber is usually a great choice. It offers ample strength and durability for everyday use without breaking the bank.

-

Performance Gear: If you're looking for carbon fiber bike components, sports equipment, or other performance-oriented gear, you might want to consider intermediate modulus (IM) or high modulus (HM) carbon fiber. These offer a higher strength-to-weight ratio, which can translate to improved performance and a more responsive feel.

-

Luxury and Style: Forged carbon fiber, with its unique marbled appearance, is often used in high-end products where aesthetics are a priority. While it may not be as strong as some other types, it still offers impressive performance and a distinctive look that's sure to turn heads.

Budget Considerations

Let's be honest, carbon fiber isn't the cheapest material out there. But there are options available for every budget. Standard modulus carbon fiber tends to be the most affordable, while high modulus and forged carbon fiber command a premium.

Consider how much you're willing to spend and what you prioritize most. If performance is your top priority, investing in a higher-modulus carbon fiber product might be worth it. But if you're looking for a stylish and durable accessory, standard modulus or forged carbon fiber could be a great option. And it by no means is flimsy.

Aesthetics

The weave pattern of carbon fiber not only affects its appearance but also its properties. Here's a quick guide:

-

Plain Weave: The classic checkerboard pattern is the most common and versatile. It offers balanced strength and a timeless look.

-

Twill Weave: This diagonal pattern is slightly more flexible and often used in parts that need to bend or curve.

-

Satin Weave: Known for its smooth, glossy finish, satin weave is often chosen for its aesthetic appeal.

Ultimately, the best weave pattern for you depends on your personal preference and the intended use of the product.

Frequently Asked Questions About Carbon Fiber Types

What are the types of carbon fiber?

Carbon fiber comes in various types based on tensile modulus (stiffness) and precursor material. Common modulus types include Standard, Intermediate, High, and Ultra-High. Precursor types include PAN-based (most common) and Pitch-based (high heat resistance).

What is the highest quality carbon fiber?

Ultra-high modulus (UHM) carbon fiber is considered the highest quality due to its extreme stiffness and strength, but it's also the most expensive. The best quality for a specific application depends on the desired properties.

What is the strongest carbon fiber pattern?

Unidirectional carbon fiber is the strongest in a single direction, but for balanced strength in multiple directions, plain weave or twill weave patterns are often preferred for their combined strength and flexibility.

Elevate Your Everyday with CFG

From the racetrack to the runway, from the aerospace industry to your everyday essentials, carbon fiber is transforming the way we design and experience the world around us. Its unique blend of strength, lightness, and aesthetic appeal has made it a favorite among engineers, designers, and enthusiasts alike.

Whether it's enhancing the performance of a high-powered sports car, enabling the creation of sleek and stylish accessories, or pushing the boundaries of technological innovation, carbon fiber is a material that embodies limitless possibilities.

At Carbon Fiber Gear, we're passionate about sharing the wonders of carbon fiber with you. Our curated collection of premium carbon fiber accessories is designed to elevate your everyday carry and infuse your life with a touch of high-tech sophistication.