Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

In the finding of new technologies, we tend to explore how we can make a different thing instead of making the same thing using different materials.

But, what if I tell you that, sometimes, the material matters?

For engineering or any other applied field, choosing suitable materials influences the overall design systems and the quality of the product.

Learn about carbon fiber filament strength and how this material will shape the future of 3D printing technology.

RELATED: Carbon Fiber Sheet Made From Petroleum Waste to Revolutionize the Automotive Industry

In this article:

- Thermoplastics Are Suboptimal for Strength Applications

- Composite Materials Have Enhanced Properties When Combined

- Chopped Carbon Fiber Filament Strength in 3D Printing

- Continuous Carbon Fiber Filament Strength in 3D Printing

- Bottom Line: Can Carbon Fiber Filaments Replace Thermoplastics?

Carbon Fiber Filaments: Superior Materials That “Shape” a New Era for 3D Printing

Thermoplastics Are Suboptimal for Strength Applications

1. Thermoplastics Are Popular in 3D Printing

If you’re tech-savvy and care about the emerging technologies around the world, you probably know about 3D printing.

This technology has dramatically altered the way we create things. Well, by “things,” I mean EVERYTHING! According to Forbes, 3D printing offers multiple applications that can revolutionize industries. From anatomical models, pharmaceuticals, and medical devices to furniture and decoration components, 3D printing has come into play and made life easier.

But, how does 3D printing work to make this technology so unique?

Unlike regular printers that use an ink cartridge to add texture to a flat surface, 3D printers use thermoplastics, like ABS or PLA, that can be melted and extruded layer by layer to form a three-dimensional object.

Because thermoplastics have a low melting point and can immediately cool after extruding from the printer nozzle, these materials are prevalent, if not “well-liked,” for 3D technology. The applications of 3D printing using thermoplastics are also rapidly expanding due to the growing qualities they bring to the table.

2. But, Are Thermoplastics Really Good for 3D Printing?

Just because something is popular doesn’t mean it’s the best choice.

So are thermoplastics.

Despite being one of the most far-reaching materials in the novel manufacturing technique, thermoplastics are not the optimal material for engineering-strength applications.

The reason is that thermoplastics tend to be ductile and not very strong or stiff, which are vital properties if you’re creating parts that require strength and durability. Imagine building a piece of 3D-printed furniture, say an armchair, and it bends or warps right the first time you use it. Of course, we don’t want it to happen. Instead, we want our products to sustain more force and be as durable as possible. But, the problem is, thermoplastics can’t withstand it!

RELATED: Mishima Builds Carbon Fiber Furniture with 3D Printing

Composite Materials Have Enhanced Properties When Combined

1. Composite Materials Allow Force Dispersion

Composite materials have recently emerged as the “savior” of 3D printing technology.

Unlike thermoplastics, composite materials are made of multiple materials, enhancing each other’s properties when combined. The result is a mixture that aggregates the best or selected qualities for broader engineering applications.

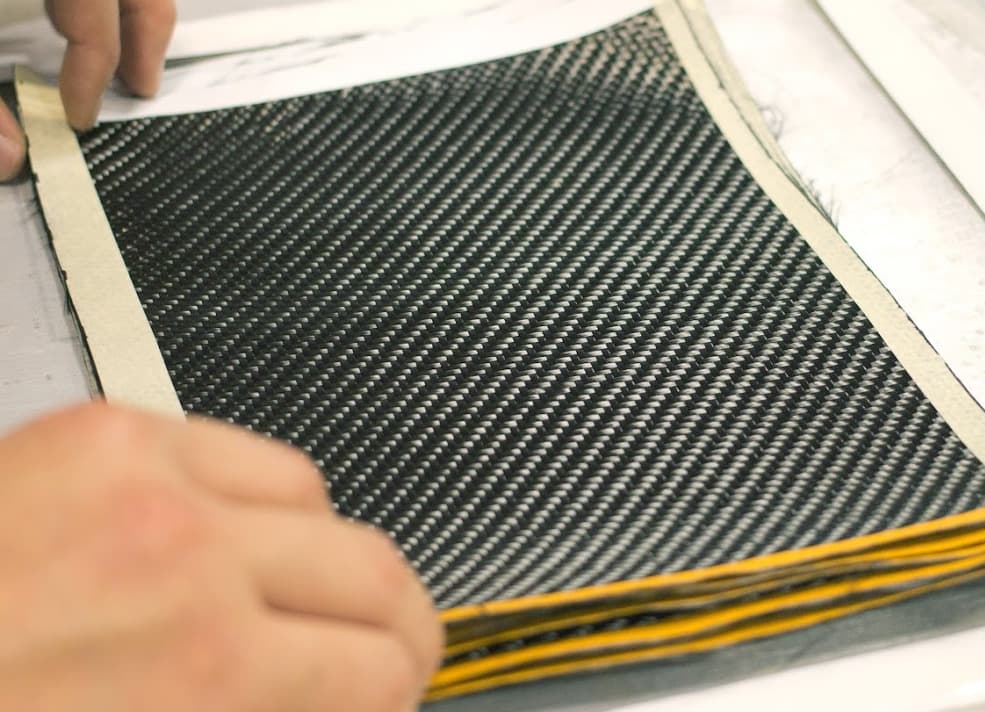

The most substantial advantage of composite materials is that they are never used alone. Instead, they are woven into continuous sheets or molded into specific shapes using a thermoset resin such as epoxy. In these optimized forms, forces can be distributed, and loads can be dispersed over the lengths of a part as multiple materials are joined together to form larger structural elements.

2. Carbon Fiber is a Common Composite Material

Carbon fiber, along with fiberglass and Kevlar, is one of the most common composite materials in various industries.

This superior material has an impressive strength-to-weight ratio, making it super strong at a lightweight. Structurally, the carbon atoms that make up the fibers are aligned into the strands, giving them an extraordinarily high tensile strength. Thermoset resins are used as the bonding agent for arranging these fibers into a specific form and curing them around a matrix material like foam.

Two forms of carbon fiber are prevalent in 3D printing: chopped carbon fiber filament and continuous carbon fiber filament.

Chopped Carbon Fiber Filament Strength in 3D Printing

1. What Are Chopped Carbon Fiber Filaments?

These strands are composed of short carbon segments mixed with traditional thermoplastics. Like concrete mixed between cement and water, the presence of carbon fiber in thermoplastics, with appropriate density and orientation, enhances the structural strength and integrity of the material.

2. Are Chopped Carbon Fiber Filaments Strong?

Filling chopped carbon fiber into thermoplastics is like upgrading the already crack-resistant material with a “strength-booster pack.”

Thermoplastics are generally resilient to snaps as they don’t break into pieces yet are easy to deform. Now, in micro-size length and great quantity, carbon fiber is there in the core of the thermoplastic strand to handle some of the applied stress on the part, improving the overall stiffness and stability of the base plastic.

So, yes. Chopped carbon fiber filaments are more robust than traditional thermoplastics. But don’t mix too many chopped carbon fibers into the plastic, or you’ll compromise the surface finish and accuracy of the part!

Continuous Carbon Fiber Filament Strength in 3D Printing

1. What Are Continuous Carbon Fiber Filaments?

In contrast to chopped carbon, continuous filaments are one single, integral strand of carbon fiber coated in a curing agent (a substance used to harden the strands). In general, continuous carbon fiber filaments are stronger than chopped carbon fibers because of the continuity that efficiently distributes the force applied to the material.

2. Are Continuous Carbon Fiber Filaments Strong?

Yes, continuous carbon fiber filaments are super strong and, by all means, are more robust than chopped carbon fibers or any other traditional material used for 3D printing.

This form of carbon fiber’s ultra robustness comes from the filaments’ continuity. Continuous strands can distribute and absorb loads over their whole length, enabling the printed item to carry higher loads and absorb greater impacts. As a result, the object can almost match the strength of metal while weighing much less.

RELATED: Ultra-lightweight & Fire-resistant Carbon Fiber Material From Trelleborg to Hit the Market

Bottom Line: Can Carbon Fiber Filaments Replace Thermoplastics?

It’s still early at this stage to confirm, but why not?

Although thermoplastics are still the predominant material for 3D printing, 3D carbon fiber filaments have all the potential to become the number one replacement

Did we mention that continuous carbon fiber filaments can also be structurally customized to further enhance their strength at the exact area for a specific purpose?

Yes, it is possible!

While making a continuous filament, you can place the carbon fibers in specific areas depending on how the part will endure loads and force, adding extra stiffness exactly where you need it. This “bonus” differs significantly from chopped fibers and thermoplastics, where stress is evenly distributed throughout the part.

Let’s say you’re using continuous filaments to make the body frame of a carbon fiber bicycle. When operating, the rider’s weight and gravity will, of course, apply to the bike. But which part of the body frame carries the most stress? It’s the joints. Continuous carbon fiber allows reinforcement in those specific areas, optimizing different loading behaviors for various applications.

In short, it’s fair enough to say that carbon fiber filaments will become the next threat to traditional plastics in 3D printing. Such an emergence will allow stronger and more durable objects to be made and possibly expand the application of 3D technology.

If you have questions about carbon fiber filament strength or any of the details discussed here, connect with us and learn more.

Interested in other CARBON FIBER products? Visit our store and take a look at our featured collections!

Personal Accessories, Clothing Accessories, Jewelry, Home & Office, Tech, Travel, Gifts, and much more!

UP NEXT:

Read more CARBON FIBER BLOGS

The Carbon Fiber Gear Blog is a lifestyle blog for carbon fiber enthusiasts where we talk about carbon fiber gear, fabrication, and news. We will round up the coolest carbon fiber products, the best gift ideas, and uses of carbon fiber.