Carbon Fiber Cars, Parts, & Care - Infographic

For lovers of carbon fiber and luxury cars, this infographic presents the current cutting-edge carbon fiber car models and tips on how to care for your carbon fiber car parts. Below the infographic, carbon fiber experts DetailedImage and CompositeWorld provide details on how to care for your carbon fiber car parts.

Carbon fiber is a leading-edge material that is currently used in aerospace, military, and high-end race vehicle manufacturing. Integrating carbon fiber into today’s assortment of performance and luxury vehicles has quickly created raving fans of the space-age material. Carbon fiber improves vehicle driving dynamics like handling, braking, and acceleration, improves frame and body strength, and even affords better impact protection in the event of a crash. For an in-depth look at the most common carbon fiber car parts, plus an assortment of intriguing facts and figures related to the contemporary material, take a look at the infographic below.

Share this Image On Your Site

How to Care for Carbon Fiber by DetailedImage.com

- For regular care of your carbon fiber car parts, it is important to think of them exactly like your paint, only softer. Meaning, most of the products you use on your paint, will work fantastic on your carbon fiber parts as well.

- Regular maintenance includes washing and drying with high-end products and techniques. This will ensure great results and less chance of implementing wash-induced imperfections.

- High-end maintenance products include automotive detailing shampoos, wash mitts, microfiber towels, etc.

- Proper protection with a wax, sealant, or coating is key to avoiding ugly oxidation and keeping your carbon fiber car parts looking their best.

- If your carbon fiber does become oxidized, you will need to machine polish or even wet sand to correct.

- Polishing can easily be performed with the right products and techniques, however, if you are not comfortable with the process we highly recommend contacting a high-end automotive detailer in your area.

- These steps above work with all carbon fiber except for dry carbon fiber. Dry carbon has completely different care options. This site, Carbon Fiber Gear, does not currently sell any dry carbon fiber items.

DetailedImage.com is the source for high end detailing supplies and information

Facts about Carbon Fiber by CompositesWorld.com

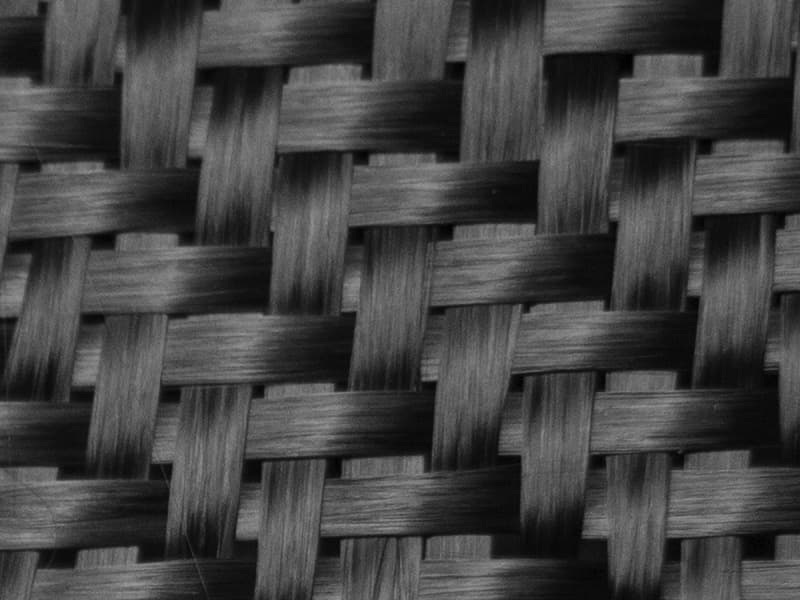

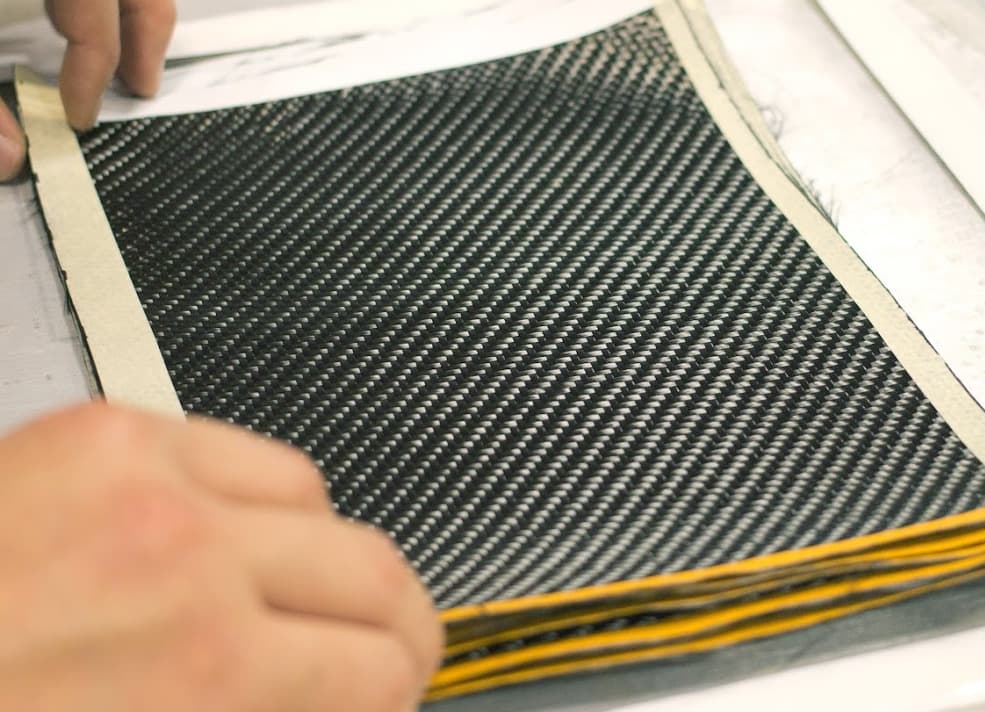

The phrase “carbon fiber” has several meanings. In popular culture, it usually means any product that is made with carbon fiber or a product made with a material that looks like carbon fiber. In the composites industry, carbon fiber is one of several fiber reinforcement types used to manufacture a composite part or structure. A composite, in turn, is a part or structure that combines a fiber reinforcement with a polymer resin of some sort. It’s this combination of fiber and resin that gives a composite its strength, stiffness and durability properties. In the composites industry, we usually specify the fiber used in a given composite part. So, we say “carbon fiber composite” or “glass fiber composite.” To the layperson, use of the phrase “carbon fiber” usually means carbon fiber composite — carbon fiber combined with a resin (usually epoxy).

How long does carbon fiber last?

Carbon fiber by itself, although a remarkable material, does not have unusual durability properties. However, when carbon fiber is combined with a resin to create a carbon fiber composite, it has strength, stiffness, and durability that are nearly impossible to match with any other material.

Carbon fiber composites don’t rust or corrode the way metals do, and they don’t rot the way wood does. Although carbon fiber composites are, pound for pound, stronger and stiffer than any other material, they can be damaged, which can create cracks and delamination (where layers of composites separate from each other), leading to failure.

How much does carbon fiber cost?

Carbon fiber (just the fiber) is available in several variations, offering a range of mechanical properties. The properties required by the composite part/structure determine the type of carbon fiber used. Because of this, the price of carbon fiber also varies, ranging from about $7/lb to several hundred dollars per pound. The most expensive, highest performing carbon fiber is most often used in aerospace and similar applications. The least expensive carbon fiber is used in things like piping, construction, and some automotive applications.

Finished carbon fiber composite parts and structures are expensive mainly because the material is expensive. In addition, fabrication methods tend to be labor-intensive, which drives up the cost. Further, in aerospace composites manufacturing, the material is cured in an industrial autoclave, which is time-consuming and expensive — and time is money.

There is a push in the industry to automate composites manufacturing, but that will drive down finished part cost only incrementally. Further, the primary benefit of automation is to bring consistency and repeatability to the manufacturing process.

Why is carbon fiber expensive?

The primary raw ingredient of carbon fiber (just the fiber) is called a precursor. The precursor is a polymer that is treated with extremely high heat and other processes to create carbon fiber. The highest quality carbon fiber is made with a precursor called polyacrylonitrile (PAN), which is based on the acrylic polymer. PAN is expensive because it is difficult to manufacture, plus it takes 2 lb of PAN to create 1 lb of carbon fiber. Further, the extremely high temperatures required to convert PAN to carbon fiber consumes a great deal of energy (and money). There is a lot of research right now looking at alternatives to PAN for carbon fiber precursors, and I expect that in the next 5-10 years we will see substantial progress in this effort.

CompositesWorld.com is a leading website for composites materials and services.