Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

In a heart-wrenching turn of events, the OceanGate Titan submersible, boasting a robust carbon fiber hull, was caught in a devastating tragedy earlier in June.

The incident has left experts and enthusiasts grappling for answers, surrounded by mystery.

Initial findings suggest that the calamity cannot only be pinned on the carbon fiber construction. Intriguingly, a web of questions unravels, igniting a quest for truth.

What truly led to the catastrophic failure of the Titan?

As investigations unfold, a tantalizing curiosity lingers, beckoning scientists and engineers to search deeper into the riddle.

In This Article:

- How Carbon Fiber Is Used On The OceanGate Titan

- What Caused The OceanGate Titan To Implode?

- Carbon Fiber Hull: Strengths And Weaknesses

- Will Carbon Fiber Be Used Again For Submersibles?

OceanGate Titan Submersible Implosion Requires Further Investigations on Its Carbon Fiber Hull

How Carbon Fiber Is Used on the OceanGate Titan

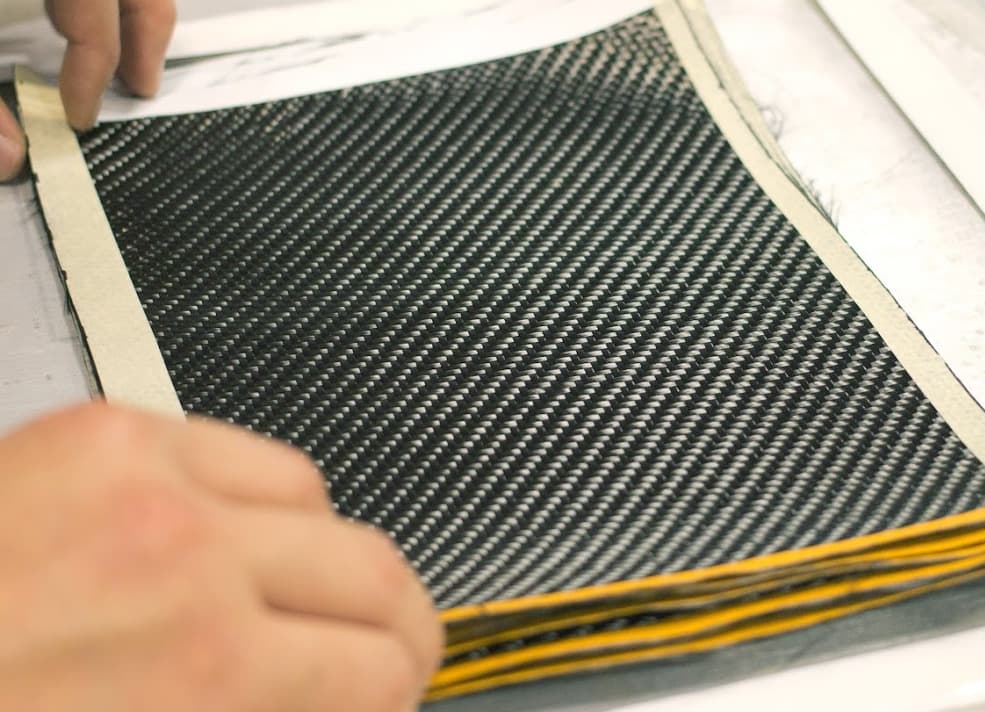

The OceanGate Titan submersible was claimed to incorporate the exceptional properties of carbon fiber to ensure its structural integrity and the safety of its crew during deep-sea explorations. Carbon fiber is renowned for its strength-to-weight ratio and lightweight yet rigid nature, making it ideal for withstanding immense compression.

Recognizing these advantages, OceanGate chose to employ carbon fiber in constructing the Titan’s hull, the primary component responsible for shielding the crew from the tremendous pressures encountered thousands of feet below the ocean’s surface.

The submersible boasts dimensions of 2.8 meters in width, 2.5 meters in height, and 6.7 meters in length. The vessel features two titanium hemispheres at the front and rear, connected to the carbon fiber hull by two titanium rings.

This assembly allows for a robust construction, weighing in at 10,432 kilograms, supposedly providing the necessary strength to accommodate a crew of five individuals.

Also, based on the significance of maintaining a watertight seal, the connection between the various components of the Titan was engineered to withstand the intense pressures of the deep sea. Notably, the viewport, which serves as an entrance and an observation window, can only be opened and closed from the outside.

This design decision reportedly ensures the secure sealing of the connecting parts, relying on bolts to prevent water leakage when subjected to pressures at great depths.

What Caused the OceanGate Titan to Implode?

Unfortunately, despite a carbon fiber hull’s inherent strength and protective capacity, the OceanGate Titan submersible ultimately succumbed to the MASSIVE compression experienced nearly 4,000 meters (13,000 feet) below the water’s surface.

This depth of pressure is FAR BEYOND what most materials or submersibles can withstand.

To put it into perspective, even the Russian Navy’s Project 941 Akula class submarine, the deepest diving submarine in the world, can only reach depths of up to 1,220 meters (4,000 feet), and it’s a military-grade vessel.

Among deep-ocean submersibles, only a few can reach that 4,000-meter depth underwater, and the most well-known one - DSV Alvin - has very limited payload capacity for equipment while only being able to accommodate a crew of 3 people.

The issue didn’t only stop there.

It was compounded by indications revealing that the OceanGate Titan had been pushed beyond its certified depth, which should be no deeper than 1,310 meters (4,300 feet). OceanGate also hinted that the carbon fiber used in the submersible’s hull came from Boeing, which had already exceeded its airplane shelf life.

This cryptic clue suggested that the submersible was likely exploited beyond its intended capacity. With carbon fiber being the primary material used in the Titan submersible, it was inevitable that it would shatter once its limitations were exceeded.

Carbon Fiber Hull: Strengths and Weaknesses

Carbon fiber has demonstrated remarkable success in various industries, such as aerospace, automotive, and sports, primarily due to its lightweight properties. However, these industries do not subject carbon fiber to the extreme compressive stresses experienced in deep-sea environments.

Consequently, the ability of carbon fiber to hold up against repeated cycles of stress, particularly under deep-sea pressures, remains unknown.

Regarding carbon fiber’s advantages, its lightweight yet rigid nature is a competitive edge, making it ideal for industries where weight reduction is a top priority. Also, its resistance to corrosion and excellent fatigue tolerance make it attractive in various applications.

However, carbon fiber does have INHERENT WEAKNESSES.

One major drawback is its tendency to shatter when its limitations are exceeded, leading to irreversible damage and potential casualties. Carbon fiber’s lack of ductility and brittleness can be problematic, especially in high-stress situations.

This limitation poses a significant challenge when designing submersibles, as the tremendous pressures experienced in the deep sea require materials capable of withstanding extreme compressive forces without failure.

Will Carbon Fiber Be Used Again for Submersibles?

The future use of carbon fiber in submersibles hinges on increased collaboration between scientists and engineers to develop a stronger composite material capable of withstanding extreme pressure at sea-bed depths.

Until such advancements are made, carbon fiber may reemerge as a viable option due to its inherent advantages, such as its lightweight nature, which enables more efficient fuel consumption and allows for greater exploring distances.

While the challenges of carbon fiber in handling compressive stress are recognized, its potential benefits cannot be disregarded. Continued research and innovation are essential to push the boundaries of material science, leading to the development of safer and more robust alternatives for submersible construction in the future.

Bottom Line

Given the circumstances the OceanGate Titan had experienced, an implosion was sadly unavoidable. The colossal pressure at such depths, combined with the misuse of the submersible, led to the catastrophic failure of the carbon fiber hull.

This unfortunate event highlights the importance of respecting the limitations of materials, including carbon fiber, in extreme environments and ensuring that safety protocols and certifications are strictly followed to prevent such failures.

Yet, amidst the quest for answers behind the tragedy, one fact remains: carbon fiber, one of the strongest materials known to humanity, will stand unyielding.

If you have questions about the use of carbon fiber by OceanGate or any details discussed here, contact us and learn more.

Are you interested in other CARBON FIBER products? Then, visit our store and take a look at our featured collections!

Personal Accessories, Clothing Accessories, Jewelry, Home & Office, Tech, Travel, Gifts, and much more!

UP NEXT:

Read more CARBON FIBER BLOGS.

The Carbon Fiber Gear Blog is a lifestyle blog for carbon fiber enthusiasts where we talk about carbon fiber gear, fabrication, and news. In addition, we round up the most fantastic carbon fiber products, the best gift ideas, and the uses of carbon fiber.