Hey, you!

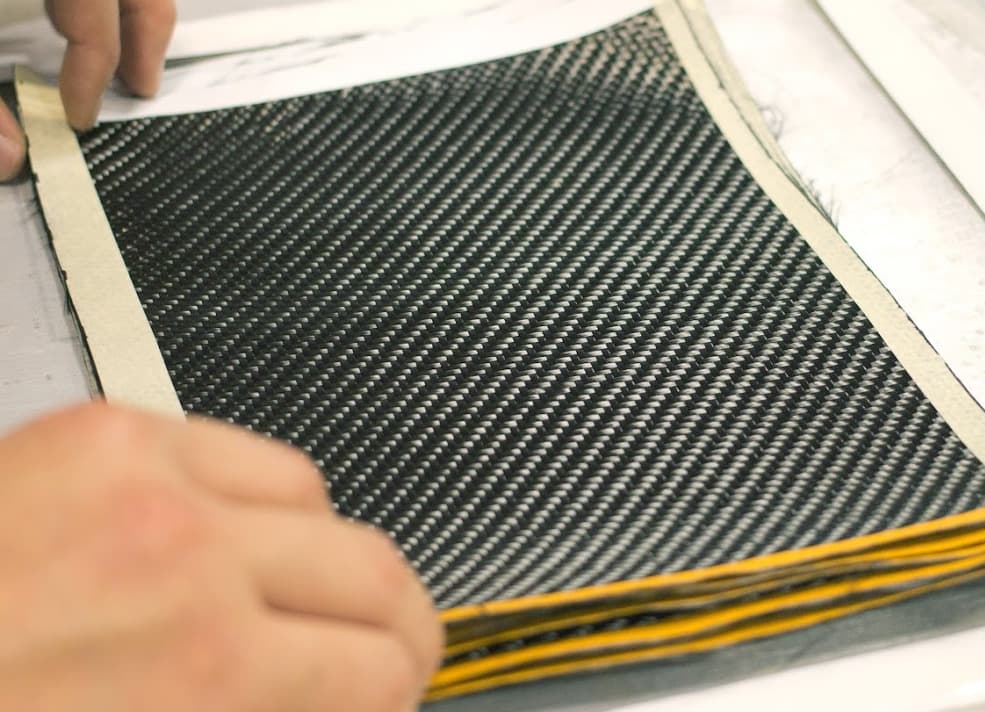

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

Did you know that despite carbon fiber being an expensive and sought-after material, a significant portion of commercial products from it ultimately end up being disposed of rather than recycled or repurposed?

This paradoxical approach to using and reusing carbon fiber has proven unsustainable in the long run. However, there is hope on the horizon with the emergence of technologies aiming to eliminate the end-of-life dilemma associated with carbon fiber.

Delve into the world of recycling carbon fiber and explore the groundbreaking efforts of a leading company that is revolutionizing how carbon fiber is brought back to life.

In This Article:

- Can Carbon Fiber Be Recycled?

- Why Is Recycling Carbon Fiber Difficult?

- What Is The New Way Of Recycling Carbon Fiber?

- How Does Recycling Carbon Fiber Change The Future?

Japanese Chemical Company Develops New Technology for Recycling Carbon Fiber

Can Carbon Fiber Be Recycled?

Yes, carbon fiber can be recycled using various methods such as mechanical, thermal, and chemical processes. However, despite its recyclability, only a small fraction of commercial carbon fiber is recycled, with approximately 10% reused.

The rest, sadly, ends up in landfills, squandering its remaining value.

There are compelling reasons why we should prioritize recycling carbon fiber. Firstly, carbon fiber and products made from this material are expensive. Compared to steel, virgin carbon fiber’s production cost is approximately 500% higher ($4 vs. $20 per kg).

In contrast, recycled carbon fiber costs only about 30% of its virgin equivalent. Therefore, recycling carbon fiber can make it more accessible to industries.

Secondly, carbon fiber production is energy-intensive, requiring 14 times more energy than steel. This higher energy demand contributes to the greenhouse gas effect, especially if carbon fiber is produced in large quantities.

Meanwhile, recycling carbon fiber requires substantially less energy than manufacturing it from scratch, reducing environmental impact.

Lastly, recycling carbon fiber offers more people access to parts made from it. Carbon fiber is primarily found in high-end products within demanding industries, leaving much of the world yearning for its benefits. Increased recycling efforts would result in a broader range of affordable carbon fiber products, benefiting various sectors and individuals.

Why Is Recycling Carbon Fiber Difficult?

As mentioned earlier, recycling carbon fiber remains challenging, with only a mere 10% of carbon fiber being successfully recycled.

Carbon fiber requires a more complex approach than metals, which can be easily recycled through thermal processes. Manufacturers are well aware of this disparity and understand that recycling carbon fiber involves groundbreaking efforts.

One of the primary difficulties lies in the composition of carbon fiber itself. Unlike metals, carbon fiber is not a uniform material. It consists of two distinct components: continuous carbon strands and a resin - an adhesive that binds the strands together.

The resin can be likened to the concrete that holds bricks together in a building. Thus, recycling carbon fiber presents a puzzling challenge: breaking down the resin without damaging or destroying the carbon strands. It’s similar to removing concrete from a brick wall without causing harm to the bricks themselves.

Various mechanical, thermal, and chemical recycling methods have been tested and utilized to address this issue. However, these methods are yet to successfully preserve the surface of the carbon fiber part without causing damage. As a result, the recycled products’ quality is typically lower than their original counterparts.

What Is the New Way of Recycling Carbon Fiber?

A Japan-based multinational chemical company, Asahi Kasei Corporation, in collaboration with the National Institute of Technology, Kitakyushu College, and Tokyo University of Science, has developed a groundbreaking technique for recycling carbon fiber.

This new method, officially known as the Electrolyzed Sulphuric Acid Solution method, enables the decomposition of the resin embedded within carbon fiber to extract continuous strands of carbon fiber indistinguishable from the original material.

Specifically, the process involves utilizing an electrolyzed sulphuric acid solution (H2SO4). This solution generates oxidative active species crucial to the decomposition process. The carbon fiber is immersed in the acid solution and heated to 100-150 °C.

This controlled heating process dissolves the resin and transforms it into carbon dioxide (CO2) and water (H2O), leaving behind only the intact carbon fiber strands. The acid solution containing the dissolved resin can be reused, resulting in minimal waste.

This innovative recycling technique offers several advantages. It allows for preserving the high-performance characteristics of carbon fiber, enabling its continued use in demanding applications. Also, it provides a cost-effective and circular solution to the end-of-life challenge associated with carbon fiber composites.

How Does Recycling Carbon Fiber Change the Future?

Asahi Kasei’s collaboration with renowned research institutions exemplifies a dedication to driving sustainable practices in the carbon fiber industry. Their groundbreaking recycling technique can bring about significant changes on a large scale.

First and foremost, it can significantly reduce waste by enabling the extraction of high-quality carbon fiber from end-of-life products. This waste reduction ensures that resources are not squandered and contributes to a more efficient circular economy.

Also, recycling carbon fiber using this innovative method can profoundly and positively impact the environment. By diverting carbon fiber from landfills and incineration, it helps mitigate the environmental consequences of disposal.

Besides, the energy-intensive process of manufacturing virgin carbon fiber can be reduced when recycled alternatives are available. These activities reduce greenhouse gas emissions and create a more sustainable footprint for carbon-based products.

The widespread adoption of this recycling technique can also have far-reaching implications for various industries. With reduced costs, the affordability of carbon-based products can improve. Until then, more individuals will have access to carbon fiber’s benefits.

If you have questions about recycling carbon or any details discussed here, contact us and learn more.

Are you interested in other CARBON FIBER products? Then, visit our store and take a look at our featured collections!

Personal Accessories, Clothing Accessories, Jewelry, Home & Office, Tech, Travel, Gifts, and much more!

UP NEXT:

Read more CARBON FIBER BLOGS.

The Carbon Fiber Gear Blog is a lifestyle blog for carbon fiber enthusiasts where we talk about carbon fiber gear, fabrication, and news. In addition, we round up the most fantastic carbon fiber products, the best gift ideas, and the uses of carbon fiber.