Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

Lamborghini supercars are world-renowned for being lightweight, aerodynamic, and quite simply, the fastest cars in the world. Since the 1980s, Lamborghini has been researching carbon fiber and has developed the technique to make it more efficient and cheaper.

RELATED: Ford's Last GT Will Be A Limited Edition Carbon Fiber Supercar

In This Article:

- The Origin of Carbon Fiber in Lamborghini Supercars

- Carbon Fiber Development in Lamborghini Supercars 2010 - 2020

- World's First Fia-Certified Carbon Fiber Roll Cage

- All Carbon Fiber Waste Utilized

Lamborghini Supercars and Carbon Fiber - 30 Years of Perfection

1. The Origin of Carbon Fiber in Lamborghini Supercars

Lamborghini first used carbon fiber in 1983. With the support of Boeing and its knowledge of Kevlar and carbon fiber being used in their crafts, it established the Esperienza Materiali Compositi department. From here, the first carbon fiber chassis was manufactured for the Countach Evoluzione, the first road car of its kind and the first of many carbon fiber cars.

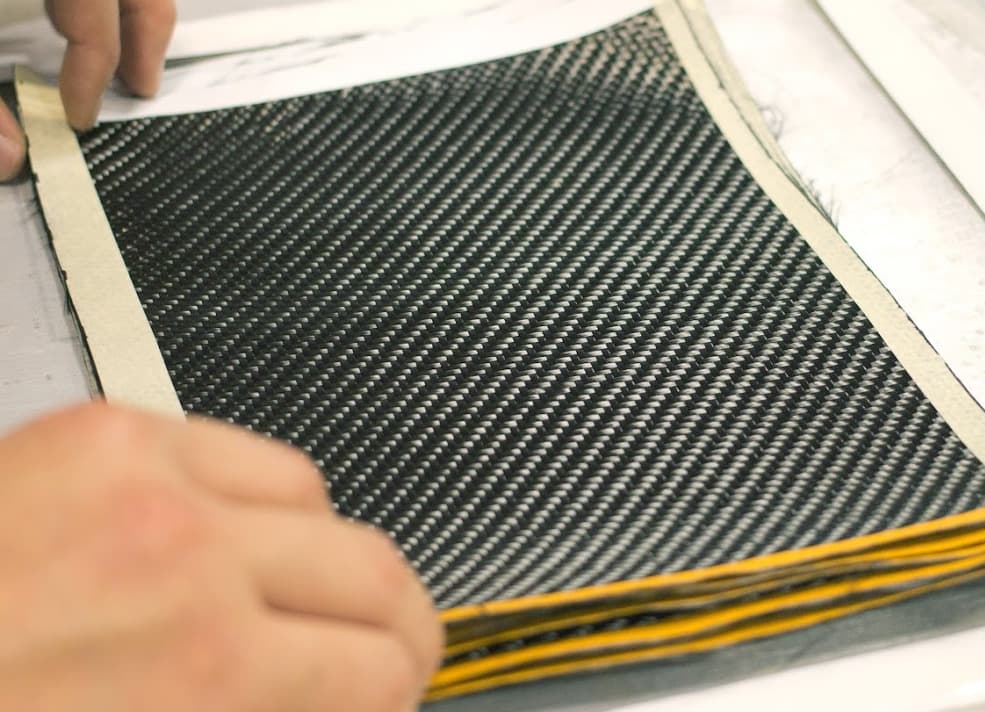

Lamborghini teamed with the University of Washington in 2007. The college assisted in the development of out-of-autoclave resin transfer molding (RTM) technology, which would later become the monocoque for the Aventador. In addition, Lamborghini's Research and Development Center established a branch to focus on novel applications for the material.

They signed another contract with Boeing in 2008, this time to research the crash behavior of composites in general and the Aventador Monocoque in particular.

Lamborghini created Forged Composites technology two years later, which led to a patent and the development of the Sesto Elemento supercar. Lambo then committed another unit to composites at its Italian location, which is where the Aventador Monocoque was eventually created.

2. Carbon Fiber Development in Lamborghini Supercars 2010 - 2020

The Lamborghini Aventador debuted in 2011. Its carbon-fiber monocoque, which weighs only 506 pounds, is made entirely in-house. Lamborghini made it in-house because the process was too complicated to outsource, according to the company. It's made by resin transfer molding, which eliminates the need for lamination and autoclaves that pure carbon fiber does. In the same year, it began working with Boeing on its RTM/carbon fiber repair technique.

Carbon skin, a flexible carbon matrix that works in automotive interiors, was created in 2015. It was created in the company's R&D division and is approved for use in automobiles. When compared to Alcantara and leather, it is lighter and softer to the touch. Lamborghini opened the Advanced Composite Structures Laboratory in Seattle in 2016 as a new carbon fiber research lab.

Lamborghini went to space in 2019. Not actually, but as part of a test campaign, it sent some supplies to the International Space Station on November 2. These experiments looked at five of the company's materials to determine how they reacted to the high strains of space travel.

3. World's First Fia-Certified Carbon Fiber Roll Cage

The crazy Essenza SCV12 was released by the Italian firm last year. It's the world's first car with an FIA-certified carbon fiber roll cage. The cage was reinforced at various spots to support 12 tons of force without considerable distortion in order to obtain that certification. The chassis, belts, pedals, and fuel tank are all subjected to more than 20 static tests.

4. All Carbon Fiber Waste Utilized

Today, the company focuses on recycling all of these composites, reducing energy use during production, and determining what to do with the byproducts. According to the company, all waste is now utilized by Lamborghini, either in the car or in the plant for things like paneling and trollies. It collects the fibers from the items it can't use and reuses them.

Lamborghini claims that their ultimate goal is to achieve true carbon fiber sustainability in their luxury cars.

If you have questions about Lamborghini supercars or any of the details discussed here, connect with us and learn more.

Interested in other CARBON FIBER products? Visit our store and take a look at our featured collections!

Personal Accessories, Clothing Accessories, Jewelry, Home & Office, Tech, Travel, Gifts, and much more!

UP NEXT:

- Bentley Releases Bentayga With World's Largest Carbon Fiber Wheels

- A Multi-Million Superyacht Concept To Be Powered By Powered Hybrid Propulsion

- 4 Great Things About Lemond's Carbon Fiber Electric Bikes

Read more CARBON FIBER BLOGS

The Carbon Fiber Gear Blog is a lifestyle blog for carbon fiber enthusiasts. We talk about carbon fiber gear, fabrication, and news. We will round up the coolest carbon fiber products, the best gift ideas, and uses of carbon fiber.