Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

For years, designers and motorcycle manufacturers have been searching for ways to lighten their bike frames. Now, thanks to modern technology, BMW is using the lightweight strength of carbon fiber to step up their game with a patent for a bolt-on motorcycle frame.

RELATED: Carbon Fiber Used In New Scuba Regulator For Greater Durability

In This Article:

Carbon Fiber Panels on Aluminum Motorcycle Frames!

How Does the Motorcycle Frame Work?

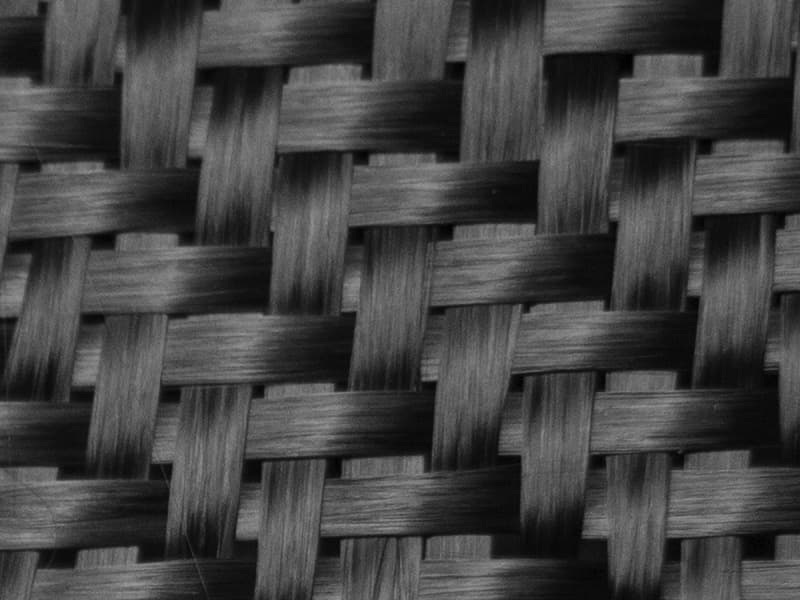

The frame is the core, the spine of the whole motorcycle design, so there's no wonder a unique yet sturdy frame is essential for practicality and style. However, carbon fiber is difficult to produce en masse, especially complex structural components.

And that's why BMW has come up with the simple idea of using a carbon fiber motorcycle frame brace. The simple idea uses strengthening panels that attach to a traditional aluminum beam frame.

RELATED: You Can Now Customize a Ford GT500 With Carbon Fiber Accessories

Motorcycle Frame Design

The motorcycle frame allows the manufacturer to create a new plating on top of the original bike frame. One advantage is that the panels are not permanently bonded, so the carbon components can simply be replaced with a new design, maybe to meet the stiffness requirements of a specific circuit or a rider's preferences. Simply altering the direction of the carbon fiber weave changes the stiffness properties of the material.

The BMW design also streamlines assembly on a manufacturing line, with more subtle benefits seen in the frame structure itself. The carbon component is depicted in the patent near the frame's corner, above the swingarm pivot, where the subframe attaches to the main chassis.

It mounts to the case through five threaded holes, four of which are already present on the existing S 1000 RR chassis. Another carbon brace will be connected to the frame's opposite side. As an added plus, the design removes the need to weld aluminum stiffeners into the chassis, which adds heat that may disrupt or affect the alloy's qualities.

A New Take on an Old Idea

You are correct in thinking that this concept is not entirely new. Today's MotoGP motorcycles often incorporate carbon reinforcing plates carefully positioned on their aluminum frames, delivering extra stiffness in torsion or flex precisely where it's needed. However, the concept has not yet made it to production motorcycles, until now, and BMW's patent adds a new twist to the concept by making the carbon pieces detachable and changeable.

Given that BMW currently has facilities devoted to mass manufacture of carbon parts, mass manufacture of bolt-on frame stiffeners would be a simple and low-cost way to incorporate the benefits of carbon into a motorbike chassis.

By mass-producing the carbon fiber motorcycle frame, BMW has once again shown the world that it has what it takes to be one of the world's top brands. BMW has the opportunity to do more than just increase the durability and performance of the bike - they can create a whole new design with the texture and color of carbon fiber.

What's your opinion on the mass production of Carbon fiber motorcycle frames by BMW? Let us know in the comments down below!

UP NEXT: