Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

Carbon fiber is one of the best materials that you can have on your car, phone cases, accessories, and everything in between.

However, like any other material, carbon fiber gets old, fades, and needs to be remedied. So, what would you do if this damage to the carbon part happened?

You fix it because it’s possible to bring carbon fiber back to life!

In this blog, we answer a few questions about returning old carbon fiber to its former shine so that you don’t have to replace carbon fiber if it cracks or fades.

RELATED: Carbon Fiber Sheet Made From Petroleum Waste to Revolutionize the Automotive Industry

In this article:

- Why Does Carbon Fiber Look Old?

- Can Carbon Fiber Be Repaired?

- Can Carbon Fiber Be Recycled?

- Should You Repair or Replace Carbon Fiber?

- How Do You Bring Carbon Fiber Back to Life?

- Best Clear Coat for Carbon Fiber

Everything You Need to Know About Refinishing Carbon Fiber

Why Does Carbon Fiber Look Old?

Like paint and metal, carbon oxidizes if it’s not maintained periodically.

Oxidation slowly degrades the outer surface of the carbon part. Over time, accumulated damage causes the glossy finish of carbon fiber to fade away, making it look dull and old.

Now that sounds familiar. Paint and metal parts exposed to oxidation also end up in the same scenario. When reacting to UV light exposure, the resin that binds carbon fibers together becomes discolored.

If this damage isn’t addressed, no amount of waxing or polishing will eventually be able to restore the gloss or fix the problem.

Can Carbon Fiber Be Repaired?

Fortunately, yes!

You can repair carbon fiber that is dull or looks faded if you know the correct technique. Depending on the level of damage, repaired carbon fiber can last a long time.

There are two types of repair: one that only intervenes with the surface of the damaged area called cosmetic repair, and one that interferes at a deeper level, called structural repair.

Cosmetic Repairs

Let’s say your sports car’s carbon fiber hood or rear spoiler picks a scratch or fades away its glossy finish after a long ride. In that case, you need cosmetic repair for the affected area to hide the flaw and make it look new.

Cosmetic repair doesn’t affect the structural integrity of the carbon fiber part, so this repair is relatively easy. Special tools aren’t necessary, although having an automatic polishing machine makes the process easier.

Structural Repairs

In a worst-case scenario where your car pumps into a pothole or another vehicle on the street, you’ll probably need a structural repair that corrects the damage.

Well, carbon fiber is tough, but it’s not unbreakable!

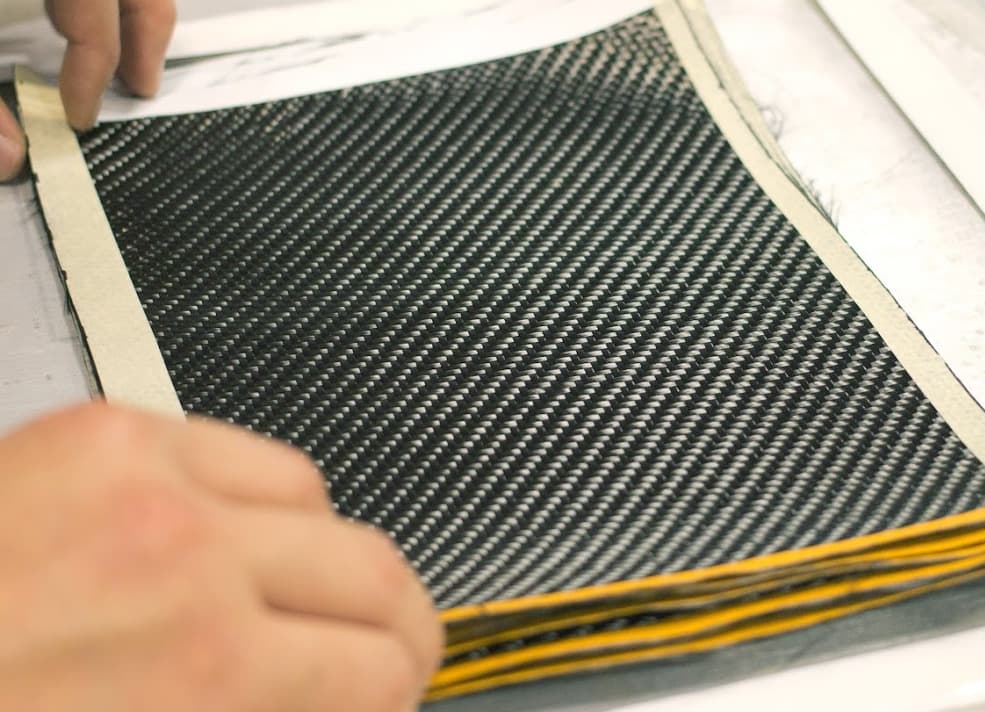

Structural repair requires more skills and involves a great deal of labor. What makes repairing carbon fiber on a structural level more intensive is that the strands on the carbon part are woven together in a particular direction. Therefore, the technician must consider the number of fibers and the fiber orientation. On top of that, each layer of carbon fiber should also match the original design to keep the same properties.

Remember that some components on your vehicle or accessories can be unrepairable. For example, friction, heat, and high forces make repairing bike rims impractical. In this case, a replacement can be a better idea.

Can Carbon Fiber Be Recycled?

What if the carbon fiber part of your car gets wrecked and can’t be repaired? It’s sad to say this, but you’ll have to dismantle and replace the component with a new one.

But don’t worry; your carbon fiber won’t end up in a landfill since this material is recyclable.

Although recycling carbon fiber is not easy, it’s a doable process. Because carbon fiber can withstand high temperatures and great physical forces, it can be broken down with chemicals to recover its original properties, preparing for a “new life.”

Repairing a hole in the middle of a door panel will be strong because the rest of the structure surrounds and supports it. On the other hand, a missing edge on a car door won't necessarily have the same support and may break again before the car's lifetime is over.

Future of Recycling Carbon Fiber

The good news is that the demand for carbon fiber is rapidly increasing. At the same time, it’ll be a massive waste if old carbon is thrown away; carbon fiber recycling is gaining more momentum to grow.

In a recent blog that we posted, Boeing has been interested in reusing scrap carbon fiber in its new airplanes in a program called ecoDemonstrator since 2010.

On the positive side, this long-term project encourages other organizations to be involved in the technology for recycling carbon fiber. Reclaiming carbon fiber also lowers the material’s price and reduces environmental impact.

So are you concerned about the quality of recycled carbon fiber? According to an article by DELL Technologies, reclaimed fibers are up to 97% as strong and functional as the originals. You won’t be able to tell the difference!

Challenges of Recycling Carbon Fiber

However, recycling carbon fiber isn’t easy, and the current technologies for this process, up until now, are still in their infancy.

It is anticipated that 30% of the newly produced carbon fiber is wasted during manufacture. Therefore, the industry may become unsustainable and unaffordable if carbon fiber is not recycled at the final production stage.

Furthermore, the end-of-life parts need a procedure to remove the resin and extract the carbon fiber. The adhesive substance is only dissolved using harsh chemicals or high temperatures, which consume a lot of energy.

RELATED: Carbon Fiber Recycling | How Boeing Turns Scraps Into Better Use

Should You Repair or Replace Carbon Fiber?

Before deciding whether to bring carbon fiber back to life, there are a few things to consider:

What is the Extent of the Damage?

Repairing a severely damaged part after an accident may not always be affordable.

Always analyze the extent of the damage and consider the time and costs involved before making a decision.

Is the Repair Worth the Cost?

To answer this question, let’s make a simple calculation. Between repairing and buying a carbon fiber car hood, which is cheaper? Repairing seems to be more practical.

But what about repairing and buying a carbon fiber bike fork? No one will ever choose to spend time and effort trying to fix it. Not in a million years!

Will the Repair Last Long Enough?

Repairing a hole in the center of a car door panel will be practical because the rest of the structure is strong enough to support and allow it to last.

On the other hand, a missing edge on a car door won’t necessarily have the same support. It may break again before the car’s lifetime is over. So you don’t want your attempt to fix things to become vain, right?

Will the Repair Affect the Look?

Painting a carbon fiber component will make a repair less visible. However, you’ll see the repair on unpainted parts, which may be a problem for some people who want their repaired parts to look perfect.

How Do You Bring Carbon Fiber Back to Life?

Step 1: Remove Any Contamination on the Surface

Make sure that the part’s surface is free from contamination or oxidation. You can wash and wipe the treated area using a microfiber cloth and a cleaning spray like the Chemical Guys Scratch and Swirl Remover.

Step 2: Remove the Old or Faded Coat With Sandpaper

After cleaning the part, rub the piece with sandpaper to remove the damaged coat. Wet sanding the part’s surface should leave a tan or yellowish residue, which is what you want to see. Do this step with caution to avoid accidentally causing further damage.

Step 3: Fill Any Fissures or Deep Chips in the Clear Coat

Check the component once more for any fissures or sizable chips after it has been sanded. You must fill the cracks and chips with resin if there are defects. Let the resin cure overnight.

Step 4: Apply the New Coat and Polish Until Done

Once everything is ready, apply the new coating layer to the part and polish it with a polishing machine until the part looks shiny. You can repeat this step several times using extra layers to ensure the component absorbs a sufficient amount of the substance.

Before jumping in, there are a few things to remember:

- Sanding-off oxidation and UV damage will leave a tan or yellowish residue. If it turns gray or black, stop immediately. Dark residue means you’ve started sanding the fiber.

- Restoring faded carbon fiber is at your own risk. If you’re inexperienced or unsure, it’s always best to consult a professional.

Watch the video below from Chemical Guys for how to re-clear carbon fiber on a Nissan 370Z. This is a step-by-step video so that you won’t miss a single step. Trust me on this; these guys know what they’re doing.

RELATED: Ultra-lightweight & Fire-resistant Carbon Fiber Material From Trelleborg to Hit the Market

Best Clear Coat for Carbon Fiber

Many different products can bring carbon fiber back to life by giving it a clear coat and a glossy look. But do you know which one is the best product that works perfectly for you?

Below are the best-rated clear coats for your carbon fiber:

SprayMax 2K Glamor High Gloss Aerosol Clear

Give this little guy a shake, then spray it on your carbon fiber. The result will surely satisfy you. A gleaming, durable coat is what the product promises you. However, it would be best if you used this spray frequently, as the coat won’t last forever on the part.

Flitz Multi-purpose Polish and Cleaner

Another fantastic product on the shelf! This one’s from Flitz. Unlike the SprayMax, Flitz Multi-purpose is a coating liquid. Apply this liquid to your carbon fiber, and you’ll find it impressively polished with a bit of protection.

Dupli-Color Clear High Performance

Dupli-Color allows your worn-out carbon fiber to restore its original appearance and protects it from dust, chemicals, heat, and chipping. Highly adhesive for impressive durability, Dupli-Color clear coat has your carbon fiber covered!

Chemical Guys Wet Mirror Finish

Here we go with Chemical Guys once again! The Wet Mirror Finish enhances the appearance of a clear coat on any color paint finish for extra gloss, shine, and a deep-wet look. This formula makes any carbon fiber part look like a mirror!

Everyone loves carbon fiber. However, like expensive cars that cost more for maintenance, this premium material takes extra care to last as long as we want. Carbon fiber is a substantial investment, so ensure that you protect and maintain it properly.

If you have questions about bringing carbon fiber back to life or any details discussed here, connect with us and learn more.

Interested in other CARBON FIBER products? Visit our store and take a look at our featured collections!

Personal Accessories, Clothing Accessories, Jewelry, Home & Office, Tech, Travel, Gifts, and much more!

UP NEXT:

- This Chevy Nova SS Wrapped With Carbon Fiber Defies Muscle Car

- New Ferrari F8 Tributo by Zacoe Gets More Carbon Fiber Upgrade

- Zaunkoenig Reveals World’s Lightest Gaming Mouse Called the M2K

Read more CARBON FIBER BLOGS

The Carbon Fiber Gear Blog is a lifestyle blog for carbon fiber enthusiasts where we talk about carbon fiber gear, fabrication, and news. We will round up the coolest carbon fiber products and the best gift ideas and uses of carbon fiber.

Editor’s Note: This post has been updated for quality and relevancy.